Top Trends in Automation Robotics Transforming Industries Today

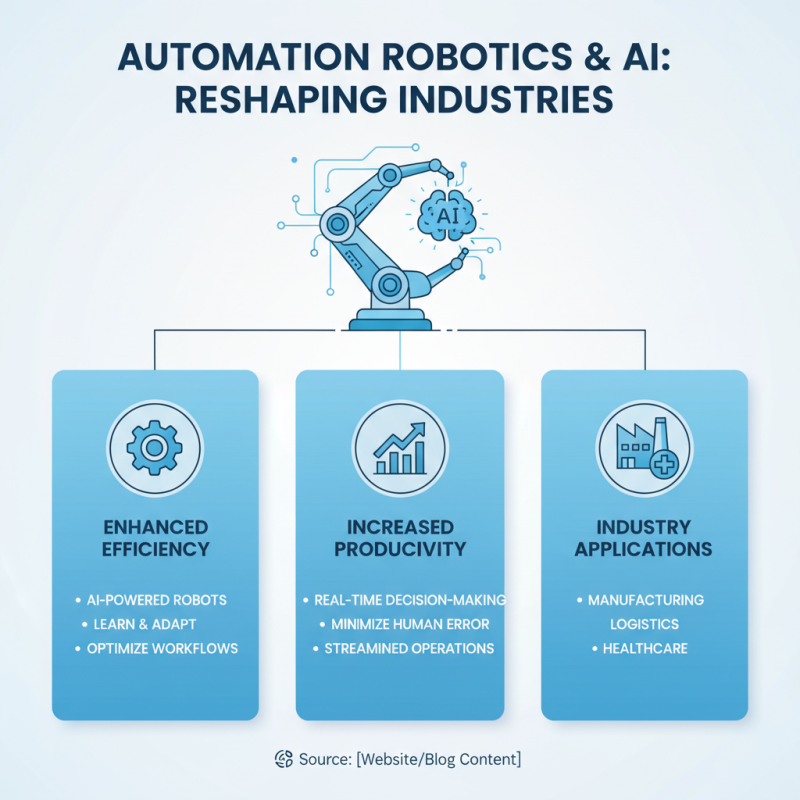

The integration of automation robotics into various industries marks a significant leap toward enhanced efficiency and productivity. According to a report by the International Federation of Robotics, the global industrial robotics market is projected to reach a staggering $75 billion by 2025, driven by rapid advancements in automation robotics technologies. The increasing adoption of these systems is not only transforming manufacturing processes but also redefining traditional roles across sectors such as logistics, healthcare, and agriculture.

Recent studies highlight that companies implementing automation robotics have observed an average productivity increase of 30% while simultaneously reducing operational costs. This technological shift is crucial for businesses aiming to remain competitive in a rapidly evolving marketplace. As organizations increasingly seek to optimize their operations, the demand for sophisticated automation robotics solutions is expected to continue growing. Understanding these top trends in automation robotics is essential for industries looking to innovate and capitalize on the myriad opportunities presented by this transformative technology, ultimately fostering a new era of operational excellence.

Key Innovations in Automation Robotics Enhancing Efficiency

In recent years, automation robotics has emerged as a pivotal force in reshaping various industries, driving innovations that significantly enhance efficiency. One of the most notable advancements is the integration of artificial intelligence (AI) with robotic systems. AI-powered robots are now capable of learning from their environments, making real-time decisions, and optimizing workflows. This capability allows companies to achieve higher productivity levels while minimizing human error. Additionally, the use of machine learning algorithms enables these robots to adapt to changing conditions, leading to more streamlined operations in manufacturing, logistics, and even healthcare.

Another key innovation is the development of collaborative robots, or cobots, which work alongside human workers. Unlike traditional robots that operate in isolation, cobots are designed to assist and enhance human capabilities. This collaboration fosters a safer and more efficient workplace, as workers can focus on more complex tasks while robots handle repetitive and menial jobs. Furthermore, advancements in sensor technology and computer vision have improved the ability of cobots to interact with their human counterparts and navigate dynamic environments. As industries embrace these innovations, the potential for increased efficiency and enhanced operational effectiveness continues to grow, ultimately transforming the landscape of work as we know it.

Impact of Robotics on Manufacturing Processes and Productivity Gains

The advent of automation robotics is revolutionizing manufacturing processes, significantly enhancing productivity across various industries. According to a recent study by McKinsey & Company, organizations that integrate advanced robotics technology can increase their operational efficiency by up to 30%, allowing for agile response to fluctuating market demands. Additionally, the International Federation of Robotics forecasts a staggering increase in robot installations, projecting that by 2025, the global stock of operational industrial robots will reach 4 million units. This growing trend underscores the importance of robotics in achieving greater output while reducing human error and operational costs.

One of the most prominent impacts of robotics in manufacturing is the drastic improvement in cycle times and throughput. For instance, the capability of robots to operate in 24/7 environments without fatigue allows manufacturers to maximize their production schedules. Furthermore, a report by the Robotics Industries Association indicates that facilities utilizing robotics have experienced productivity gains of up to 40%, translating into faster delivery times and increased customer satisfaction.

Tips: To harness the benefits of robotics, companies should start by assessing their current manufacturing processes to identify bottlenecks and areas for improvement. Emphasizing employee training on collaborative robotics can also ensure smooth integration and usage of automation technologies for the workforce. Regularly reviewing operational data will help fine-tune robotic applications, leading to sustained productivity gains.

Impact of Robotics on Manufacturing Processes and Productivity Gains

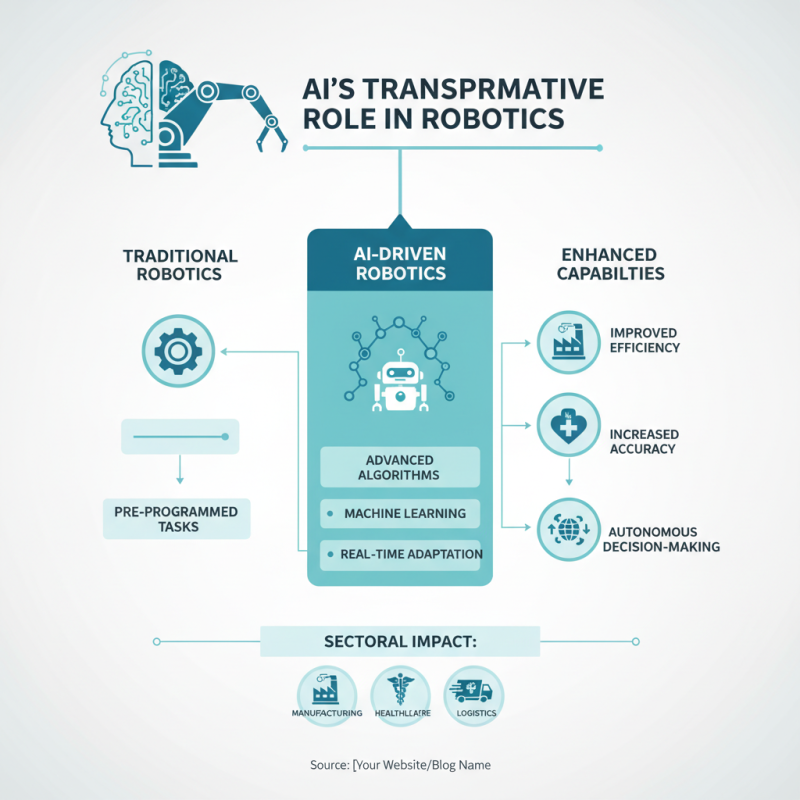

The Role of AI in Automating Robotics Operations Across Sectors

AI is playing a transformative role in the field of robotics, significantly enhancing the capabilities of automated systems across various sectors. By integrating advanced algorithms and machine learning techniques, AI enables robots to not only follow pre-programmed instructions but also adapt to dynamic environments and circumstances. This evolution allows for real-time decision-making, improving efficiency and accuracy in operations. As a result, industries such as manufacturing, healthcare, and logistics are witnessing a substantial increase in productivity thanks to AI-driven automation.

Moreover, AI enhances the cognitive abilities of robots, enabling them to perform complex tasks that require human-like thinking. For instance, in manufacturing, robots equipped with AI can analyze workflows, predict maintenance needs, and adjust their performance based on real-time feedback. In healthcare, AI-powered robotic systems can assist in surgeries, providing precision and reducing recovery times. These advancements signify a shift towards more intelligent robotic systems capable of self-improvement and learning from their experiences, ultimately leading to a new era of automation where collaboration between humans and machines is more seamless than ever.

Future Trends: Collaborative Robots and Human-Robot Interaction

The evolution of collaborative robots, or cobots, is a significant trend reshaping industries today. According to a report by Research and Markets, the collaborative robotics market is projected to reach $12.3 billion by 2025, expanding at a compound annual growth rate (CAGR) of over 30%. This shift highlights the growing acceptance of human-robot interaction on the factory floor, where cobots are designed to work alongside humans, enhancing productivity and safety. These robots can handle repetitive or physically demanding tasks, allowing human workers to focus on more complex and value-added activities.

Moreover, the integration of advanced sensors and artificial intelligence into cobots has significantly improved their ability to adapt to real-time changes in the workspace. A study by the International Federation of Robotics (IFR) found that 87% of manufacturing companies believe the implementation of human-robot collaboration will significantly improve operational efficiency. As workplace dynamics evolve, organizations are increasingly recognizing the importance of seamless collaboration between humans and robots, fostering a more flexible and innovative environment.

These trends indicate a promising future where human-robot interaction plays a central role in driving efficiency and productivity across various sectors.

Challenges and Solutions in Implementing Automation Robotics Today

Implementing automation robotics in various industries presents significant challenges that organizations must navigate to reap the benefits of this technology. One of the primary hurdles is the resistance to change from the workforce. Employees may feel threatened by the introduction of robotics, fearing job displacement or the need for unfamiliar skills. To address this, companies can invest in comprehensive training programs that not only educate the workforce on how to operate alongside robotics but also emphasize the role of automation in enhancing job satisfaction and productivity. By fostering a collaborative environment where human workers and robots coexist, organizations can mitigate fears and promote acceptance of technology.

Another critical challenge lies in the integration of automation robotics with existing systems and processes. Many industries have legacy systems that are not easily compatible with new robotic technologies. To solve this, organizations must carefully evaluate their infrastructure and consider modular automation solutions that can be tailored to their specific needs. This approach allows businesses to incrementally integrate automation without entirely overhauling their systems. Furthermore, adopting standard communication protocols between robots and existing technologies can streamline operations and enhance the efficiency of deployment. By approaching integration thoughtfully, industries can better position themselves to leverage automation robotics effectively.

Related Posts

-

10 Automation Robotics Tips to Maximize Efficiency in Your Processes

-

How to Choose the Best Robot Tech for Your Business Needs

-

2025 How to Harness Robot Tech for Business Success and Innovation

-

Top 5 Robotics in Supply Chain: Revolutionizing Efficiency and Productivity

-

Top 10 AGV Vendors Revolutionizing Warehouse Automation and Logistics in 2023

-

Understanding the Future of Logistics with Advanced AGV Systems in Modern Warehousing