Why You Need Supply Chain Automation Tools for Business Efficiency

In today's fast-paced business environment, the efficiency of supply chain operations can make or break a company’s success. As businesses strive to enhance productivity and minimize operational costs, the adoption of supply chain automation tools has emerged as a critical strategy. According to Emma Thompson, a renowned supply chain management expert, "Investing in supply chain automation tools not only streamlines processes but also provides invaluable insights that drive informed decision-making."

By automating supply chain tasks, organizations can reduce human error, improve speed, and enhance overall service quality. The integration of advanced technologies such as artificial intelligence, machine learning, and data analytics into these tools enables businesses to gain real-time visibility and control over their supply chain activities. This transformation not only fosters operational effectiveness but also positions companies to respond agilely to market changes and customer demands.

As competition heightens and customer expectations evolve, the importance of supply chain automation tools cannot be overstated. Businesses that embrace these technologies are not just improving their internal processes but are also setting themselves up for sustainable growth and success in a volatile marketplace. Transitioning towards an automated supply chain not only optimizes resources but also lays a foundation for strategic innovation and long-term profitability.

Understanding Supply Chain Automation and Its Importance

Supply chain automation refers to the utilization of technology to manage and streamline supply chain processes, significantly enhancing operational efficiency. By integrating various automated systems, businesses can reduce manual tasks, minimize errors, and improve the speed of information flow across the supply chain. This automation encompasses everything from inventory management and order processing to demand forecasting and supplier collaboration. Understanding the intricacies of supply chain automation is crucial for any business seeking to maintain competitiveness in an increasingly fast-paced market.

The importance of supply chain automation lies in its ability to provide real-time insights and analytics, which are essential for informed decision-making. Automated systems collect and analyze data from various sources, helping businesses predict demand fluctuations and respond proactively. Additionally, automation promotes better inventory control, enabling companies to optimize stock levels, thereby reducing holding costs and enhancing customer satisfaction. As consumer expectations continue to rise, embracing supply chain automation is not just beneficial but essential for achieving long-term business efficiency and success.

Key Benefits of Supply Chain Automation for Business Efficiency

Supply chain automation tools are increasingly essential for businesses seeking to enhance their operational efficiency. According to a report by McKinsey, companies that implement automation in their supply chains can reduce operational costs by up to 30%. This significant reduction is primarily achieved through streamlined processes, which minimize human error and improve speed in order fulfillment. By automating repetitive tasks such as inventory management and order processing, businesses can allocate resources more effectively and focus on strategic initiatives that drive growth.

Moreover, the adoption of automated supply chain solutions leads to improved data accuracy and real-time visibility across the supply chain. Research from the Institute for Supply Management indicates that organizations with automated systems experience a 20% increase in forecasting accuracy. This enhanced data analysis capability enables businesses to make informed decisions, optimize stock levels, and enhance customer satisfaction through timely deliveries. Ultimately, supply chain automation not only boosts efficiency but also fosters a more agile business model, allowing companies to quickly adapt to market changes and customer demands.

Types of Supply Chain Automation Tools and Their Functions

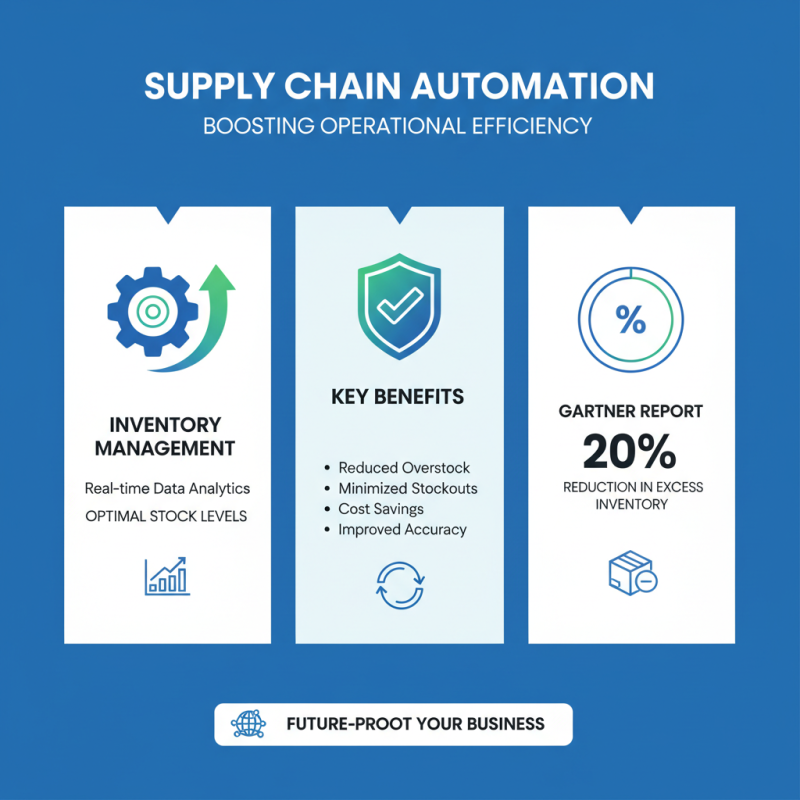

In today's fast-paced business environment, supply chain automation tools play a pivotal role in enhancing operational efficiency. There are several types of automation tools available, each designed to optimize different facets of the supply chain. For instance, inventory management systems utilize real-time data analytics to help businesses maintain optimal stock levels, reducing both overstock and stockouts. According to a report by Gartner, improving inventory accuracy through automation can lead to a reduction in excess inventory by up to 20%, directly impacting a company’s bottom line.

Another category of supply chain automation tools encompasses transportation management systems (TMS), which streamline the planning and execution of the movement of goods. TMS software can significantly lower transportation costs by providing data-driven insights on route optimization and carrier selection. A study by McKinsey & Company indicates that companies implementing TMS can achieve cost savings of 10% to 15% on freight expenses through improved efficiency and better decision-making capabilities.

Furthermore, order fulfillment automation tools transform how businesses process customer orders. These tools can automate various stages of fulfillment, from order entry to shipping, enhancing speed and accuracy. A recent survey by Supply Chain Dive found that 67% of organizations that integrated fulfillment automation reported a marked increase in customer satisfaction due to faster delivery times. By leveraging these automation tools, businesses not only streamline their operations but also create a more agile and responsive supply chain overall.

Challenges in Implementing Supply Chain Automation Solutions

Implementing supply chain automation solutions can present a multitude of challenges that organizations must navigate to achieve operational efficiency. One major hurdle is the integration of new technologies with existing systems. Many companies have legacy systems that may not be compatible with modern automation tools. This can lead to disruptions, increased costs, and the need for extensive training for employees who must adapt to the new technology. Therefore, careful planning and strategic alignment are necessary to ensure that the transition is smooth and beneficial.

Another challenge is the resistance to change within the organization. Employees may feel threatened by automation, fearing job loss or increased workloads related to the transition. This can lead to a lack of buy-in from staff, making it critical for leaders to communicate the benefits of automation clearly and provide necessary support throughout the process. Engaging employees in training sessions and demonstrating how automation can enhance their work rather than replace it can help alleviate fears and foster a more collaborative environment for implementing these new solutions.

Future Trends in Supply Chain Automation and Business Growth

The landscape of supply chain automation is set to evolve rapidly in the coming years, driven by advancements in technology and changing market demands. One of the most significant trends is the integration of artificial intelligence (AI) and machine learning into supply chain management. These technologies enable businesses to analyze vast amounts of data in real-time, optimizing inventory levels, forecasting demand more accurately, and enhancing decision-making processes. As AI continues to mature, organizations will likely achieve greater operational efficiency and responsiveness to customer needs.

Moreover, the implementation of the Internet of Things (IoT) will further revolutionize supply chain practices. By connecting devices and sensors throughout the supply chain, companies can gain unprecedented visibility and control over their operations. This connectivity allows for real-time tracking of products, improved logistics management, and a more agile response to disruptions or delays. As businesses embrace IoT technology, they will not only enhance their operational capabilities but also foster stronger relationships with suppliers and customers, ultimately driving growth in an increasingly competitive marketplace.

Why You Need Supply Chain Automation Tools for Business Efficiency - Future Trends in Supply Chain Automation and Business Growth

| Dimension | Description | Current Trends | Future Projections |

|---|---|---|---|

| Automation Technology | Tools and systems for streamlining operations. | Increased use of AI and machine learning. | Emergence of fully autonomous supply chains. |

| Cost Efficiency | Reduction of wasted resources and labor costs. | Improved inventory management practices. | Significant cost reduction leading to higher profits. |

| Real-Time Data | Immediate access to supply chain data analytics. | Growth of IoT devices for data collection. | Real-time decision making based on predictive analytics. |

| Customer Satisfaction | Improving the customer experience through faster delivery. | Focus on personalized service and responsiveness. | Integration of supply chains directly with customer feedback. |

| Sustainability | Eco-friendly practices in supply chain processes. | Rise in demand for sustainable sourcing. | More businesses adopting circular economy principles. |

Related Posts

-

Top 10 Benefits of Supply Chain Automation for Your Business Success

-

Top 10 Mobile Robots Revolutionizing Automation in 2023

-

10 Automation Robotics Tips to Maximize Efficiency in Your Processes

-

Top 5 Robotics in Supply Chain: Revolutionizing Efficiency and Productivity

-

Understanding the Future of Logistics with AGV AMR Technology Innovations

-

2025 How to Choose the Best Picking Robots for Your Warehouse Efficiency