How to Ensure Robot Safety Standards are Met in 2025

As the integration of robotics continues to proliferate across various industries, ensuring compliance with robot safety standards has become paramount. According to the International Federation of Robotics, the global stock of operational industrial robots is projected to reach 4 million units by 2025, underscoring the urgent need for robust safety measures. With this rapid growth, industries must prioritize the adherence to established safety standards to protect workers and optimize operational efficiency.

Furthermore, a report by the Robotics Industries Association highlights that nearly 40% of robotic accidents are attributed to improper safety protocols and lack of adherence to standards. As robots and humans work side by side in increasingly collaborative environments, the intricacies of robot safety standards must evolve to address emerging risks and technologies. As we progress toward 2025, businesses must not only understand existing regulations but also anticipate future developments to ensure comprehensive safety frameworks are in place.

In this ever-evolving landscape, stakeholders must collaborate to establish and refine guidelines that not only comply with current robot safety standards but also embrace innovation. By doing so, industries can create safer work environments, reduce the incidence of accidents, and ultimately enhance productivity, paving the way for a responsible and sustainable robotic future.

Understanding the Importance of Robot Safety Standards in 2025

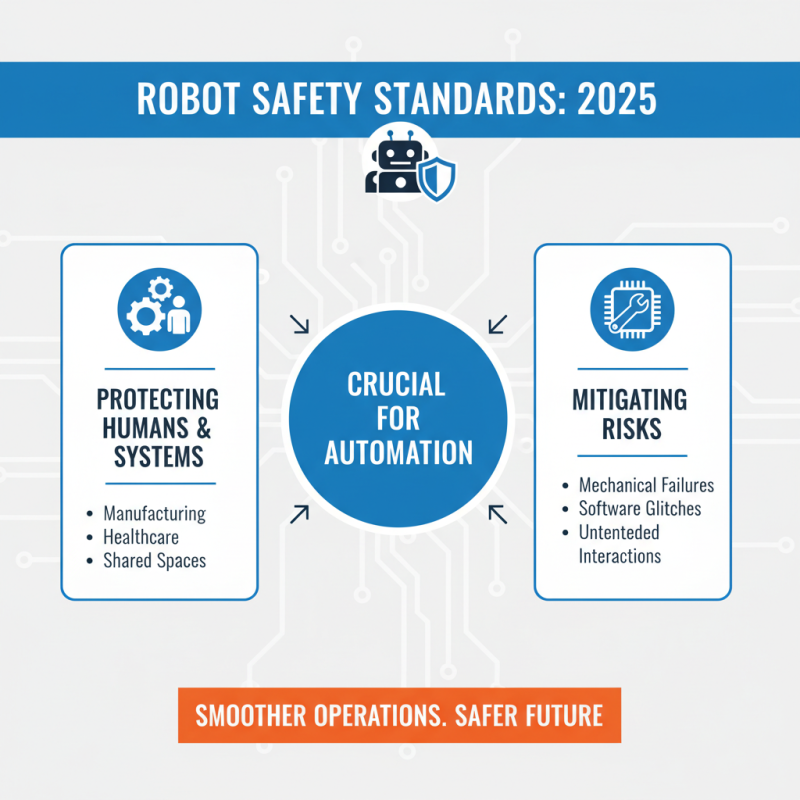

In 2025, the significance of robot safety standards has never been more pronounced as industries increasingly rely on automation. As robots become integral to various sectors, from manufacturing to healthcare, ensuring their safe operation is crucial not just for protecting human workers but also for the smooth functioning of technological systems. Robust safety standards help mitigate risks associated with robotic operations, which can include mechanical failures, software glitches, or unintended interactions with humans in shared spaces.

Understanding the importance of these safety standards goes beyond mere compliance; it encapsulates a holistic approach to risk management. Adhering to established safety protocols fosters trust among employees and the public, promoting a culture of safety and innovation. By prioritizing thorough risk assessments, regular maintenance routines, and comprehensive training programs, organizations can create environments where robots enhance productivity without compromising safety. As we move further into an automated future, the commitment to robust safety measures will be pivotal in maximizing the benefits of robotics while minimizing potential hazards.

Key Regulatory Bodies Influencing Robot Safety Standards

In 2025, the landscape of robot safety standards will be shaped significantly by various key regulatory bodies. These organizations are tasked with the critical responsibility of establishing guidelines that ensure robotics technology operates within safe parameters. Among the most influential bodies are international standards organizations, national regulatory agencies, and industry-specific groups, each contributing unique insights and requirements that govern robot safety.

International bodies like the International Organization for Standardization (ISO) play a pivotal role by developing comprehensive standards that set benchmarks for safety in robotic systems globally. Their focus extends to risk assessment, user interaction, and interoperability of robotic systems, making sure that these machines can be safely integrated into various environments. Similarly, national regulatory agencies—such as the Occupational Safety and Health Administration (OSHA) in the United States—tailor these international standards to fit the specific legal frameworks and safety protocols of their regions, ensuring compliance across different sectors.

Industry-specific organizations also exert considerable influence by addressing the unique challenges posed by robotics in sectors such as healthcare, manufacturing, and transportation. These groups work closely with developers and users to create practical safety measures that reflect the realities of specific applications. By fostering collaboration between stakeholders, they can anticipate future safety concerns and refine existing standards to mitigate risks associated with the adoption of advanced robotic technologies.

How to Ensure Robot Safety Standards are Met in 2025 - Key Regulatory Bodies Influencing Robot Safety Standards

| Regulatory Body | Region | Key Regulations | Compliance Date | Impact Area |

|---|---|---|---|---|

| ISO | Global | ISO 10218 | 2025 | Industrial Robots |

| ANSI | United States | ANSI/RIA R15.06 | 2025 | Service Robots |

| EU Robotics | Europe | EU Machinery Directive | 2025 | Consumer Robotics |

| JIS | Japan | JIS B 8435 | 2025 | Collaborative Robots |

| IEC | Global | IEC 61508 | 2025 | Safety Systems |

Essential Safety Measures for Robotics Development and Deployment

As robotics continues to evolve, ensuring safety standards becomes a critical component of development and deployment. Essential safety measures start with a robust framework for risk assessment during the design phase. Developers must implement systematic hazard identification and mitigation strategies that address mechanical, electrical, and software-related risks. This proactive approach requires a multidisciplinary team that includes engineers, safety experts, and regulatory professionals to collaboratively evaluate potential safety concerns and establish protocols to minimize them.

In addition to rigorous design processes, comprehensive testing protocols are vital. Robotics must undergo thorough simulation and real-world testing to assess performance under varying conditions. Utilizing advanced testing environments allows developers to identify vulnerabilities and rectify them before deployment. Furthermore, ongoing training and education for users and operators of robotic systems are crucial in maintaining safety standards. By promoting an understanding of the technology and its functionalities, organizations can create a culture of safety that extends beyond mere compliance, ensuring that robots are not only effective but also safe for all participants in their operational environment.

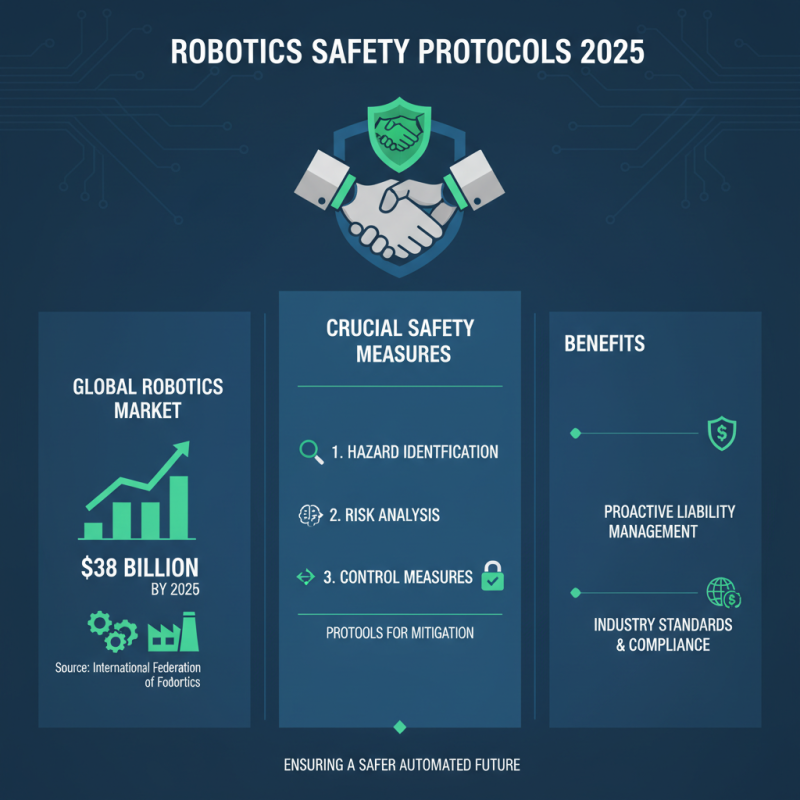

Implementing Risk Assessment Protocols for Robotics

As the robotics industry evolves rapidly, implementing robust risk assessment protocols is crucial for ensuring safety standards by 2025. According to a report from the International Federation of Robotics, the global market for industrial robots is expected to reach $38 billion by 2025, which underscores the need for comprehensive safety measures. These protocols should encompass hazard identification, risk analysis, and control measures to mitigate potential dangers associated with robotic systems. By conducting rigorous risk assessments, organizations can proactively manage liabilities and ensure compliance with industry standards.

Furthermore, a recent study highlighted that nearly 50% of workplace accidents involving robotics could have been prevented with appropriate risk management strategies in place. This statistic emphasizes the importance of not only focusing on the technical specifications of robotic designs but also on the human-robot interaction protocols. Effective risk assessment must include evaluating environmental factors, operator training, and the potential for equipment failure. Adopting a systematic approach to risk assessment will enable organizations to create safer work environments and foster greater innovation while reducing the likelihood of injuries and operational disruptions.

Future Trends in Robot Safety Compliance and Monitoring

As we look toward 2025, the future of robot safety compliance and monitoring presents both challenges and opportunities. Automation continues to integrate deeper into our industries, necessitating a proactive approach to ensure that safety standards evolve in tandem with technology. Key trends include the advancement of AI in risk assessment, the use of real-time monitoring systems, and a focus on collaborative robots that must work safely alongside human operators.

To enhance safety compliance, companies should implement robust training programs for employees to understand the operational limits and safety protocols of new robotic systems. Regular audits and updates of safety procedures are crucial, as they help adapt to the rapid changes in robotic capabilities.

Another important tip is to leverage data analytics to monitor robot performance continuously. Utilizing sensors and machine learning algorithms can lead to early detection of potential safety hazards, allowing for timely interventions. Furthermore, developing a culture of safety that involves all staff members can empower teams to prioritize compliance and proactively share feedback on safety issues. By embracing these strategies, organizations will be better equipped to meet and maintain robot safety standards in the exciting landscape of 2025.

Robot Safety Standards Compliance Trends in 2025

Related Posts

-

Why is AGV Technology Revolutionizing Material Handling in Warehousing?

-

Enhancing Warehouse Efficiency: The Impact of AGV Systems on Operational Costs and Throughput

-

2025 Guide: How to Choose Between AGV and AMR for Your Warehouse Needs

-

Top 10 Benefits of Material Handling Robots for Your Business Efficiency

-

How to Implement an Automated Guided Vehicle System in Your Warehouse Operations

-

Top 10 Benefits of Supply Chain Automation for Your Business Success