2025 Guide: How to Choose Between AGV and AMR for Your Warehouse Needs

In the rapidly evolving landscape of warehouse automation, choosing the right technology can be a daunting task for business owners. As industries increasingly look to improve efficiency and reduce operational costs, the decision between Automated Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs) has become crucial. According to Dr. Emily Chen, a leading expert in warehouse logistics, “Understanding the unique capabilities of AGVs and AMRs is essential for any organization aiming to enhance productivity while maintaining flexibility in their operations.”

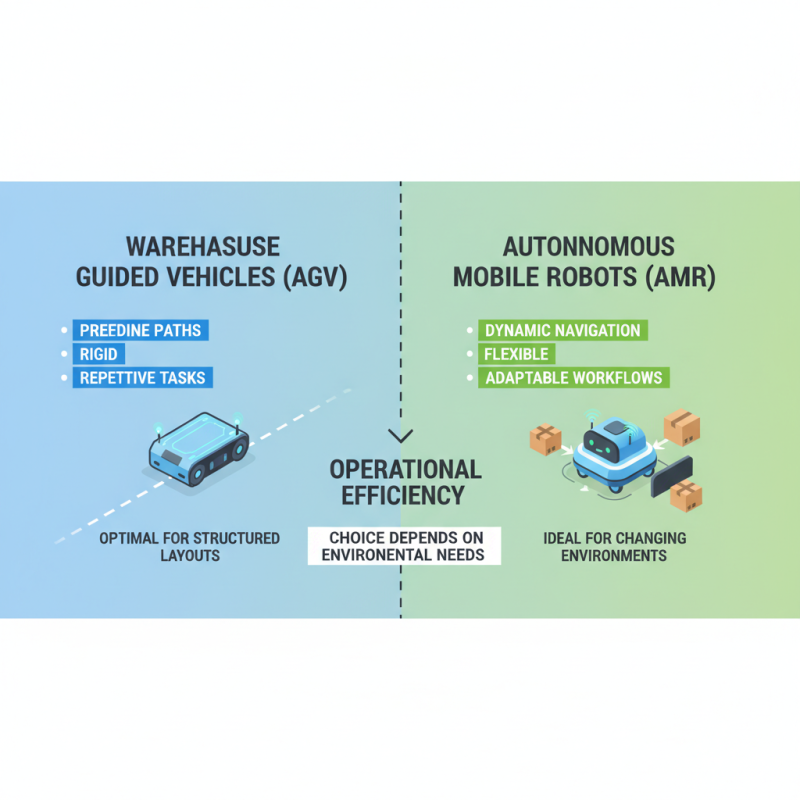

The distinctions between AGV and AMR technologies can significantly impact the effectiveness of warehouse operations. AGVs typically follow predetermined paths and are ideal for performing repetitive tasks in structured environments, while AMRs utilize advanced sensors and AI algorithms to navigate dynamically, adapting to changing conditions in real-time. As such, businesses must carefully assess their specific needs, workflows, and existing systems before making a choice.

This guide aims to elucidate the fundamental differences and use cases for AGV and AMR systems, providing insights to help warehouse managers make informed decisions tailored to their operational demands. As the demand for automation continues to rise, understanding the critical features and advantages of each technology will empower organizations to select the optimal solution for their warehouse needs.

Understanding AGVs: Definition and Key Features

Automated Guided Vehicles (AGVs) are essential components in modern warehouses, designed to optimize material handling and improve operational efficiency. AGVs are mobile robots that follow predefined paths or routes within a facility, transporting goods from one location to another with minimal human intervention. Typically equipped with sensors, cameras, and navigation technology, these vehicles can safely navigate complex environments, avoiding obstacles and ensuring timely delivery of materials.

One of the key features of AGVs is their ability to operate continuously, often without the need for breaks, thereby enhancing productivity levels. They can be programmed to handle various tasks, such as moving inventory from receiving areas to storage locations or assisting in order fulfillment processes. AGVs can also be integrated with warehouse management systems (WMS) to streamline operations further, allowing for real-time tracking and data collection. Their flexibility in route programming and adaptability to changing layouts make AGVs an invaluable asset for warehouses looking to maintain a competitive edge in an increasingly automated industry.

2025 Guide: AGV vs AMR Warehouse Solutions

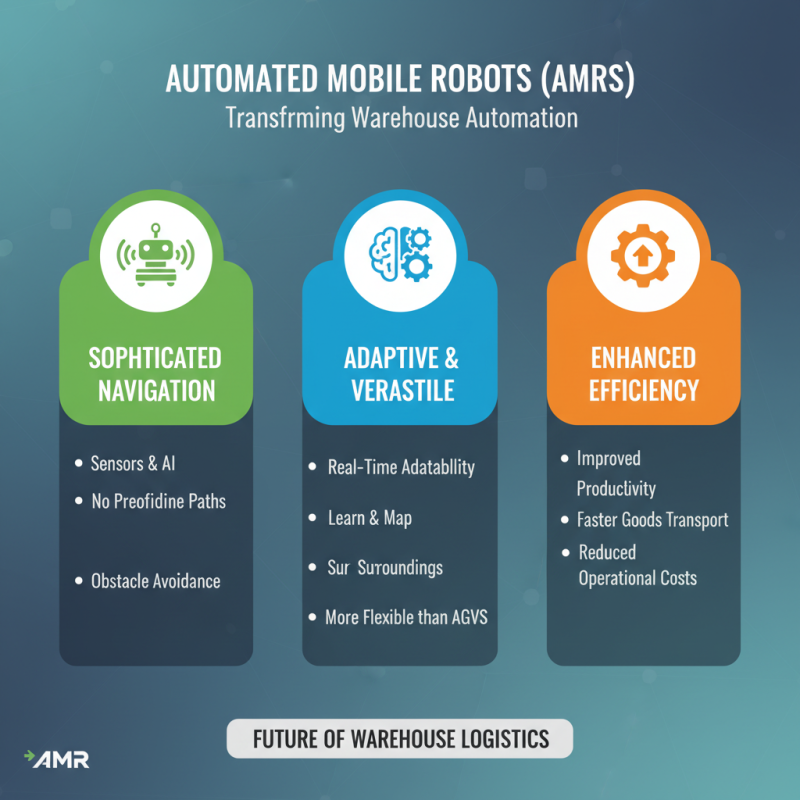

Exploring AMRs: Definition and Distinct Advantages

Automated Mobile Robots (AMRs) represent a significant advancement in warehouse automation, transforming how goods are handled and transported within facilities. By utilizing sophisticated sensors and artificial intelligence, AMRs can navigate complex environments, avoiding obstacles and adapting to real-time changes. This capability allows them to operate without predefined paths, making them more versatile compared to traditional Automated Guided Vehicles (AGVs). With the ability to learn and map their surroundings, AMRs can enhance operational efficiency and productivity.

The distinct advantages of AMRs extend beyond navigation. Their flexibility in layout and deployment means warehouses can easily adapt to evolving storage requirements or workflow changes without the need for significant infrastructure modifications. Moreover, AMRs can operate collaboratively with human workers, enhancing safety and optimizing productivity. As they become increasingly capable of performing a variety of tasks—from inventory management to order fulfillment—they provide warehouses with a competitive edge in a fast-paced market. Thus, understanding the unique features and benefits of AMRs is essential for warehouses looking to modernize their operations and maximize efficiency.

Comparing Operational Efficiency: AGVs vs. AMRs

When it comes to enhancing operational efficiency within warehouse environments, the choice between Automated Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs) is critical. AGVs typically operate on predefined paths, following magnetic strips or floor markings. This method offers reliable and consistent transport for materials but may lack flexibility in dynamic environments. Thus, while AGVs excel in repetitive tasks and are well-suited for structured warehouse layouts, their operational efficiency can be restricted in scenarios that require adaptability to changing workflows.

On the other hand, AMRs utilize advanced sensors and artificial intelligence to navigate and understand their surroundings, allowing them to operate more autonomously. This capability enables AMRs to reroute themselves in real-time, make decisions about the best paths to take, and integrate seamlessly into ever-evolving warehouse systems. As a result, AMRs can enhance operational efficiency by reducing downtime and increasing the speed of material handling. However, this flexibility might come with a higher initial investment and requires ongoing technological support.

Ultimately, the decision on which system to implement should be guided by a thorough assessment of the specific operational needs and goals of the warehouse. Consideration of factors like layout complexity, scalability, and long-term investment will play significant roles in determining whether AGVs or AMRs are the better fit for achieving optimal operational efficiency.

Evaluating Cost: Initial Investment and Long-term Savings

When deciding between Automated Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs) for your warehouse, evaluating costs is crucial. Initial investment can vary significantly based on the technology, complexity, and integration capabilities of the system you choose. AGVs generally require a more substantial upfront cost due to the need for fixed infrastructure, like magnetic strips or guides, which can drive up installation expenses. On the other hand, AMRs are often seen as more flexible and cost-effective for initial deployment, as they can operate in dynamic environments without extensive infrastructure modifications.

Long-term savings are another critical factor in your decision-making process. While AGVs may have lower operational costs due to their straightforward programming in fixed paths, they often lack the adaptability of AMRs, which can optimally navigate changing warehouse layouts. This flexibility can lead to savings in labor costs and improved operational efficiency over time.

Moreover, AMRs' capabilities in integrating with advanced data analytics mean they can optimize routes and workflows in real time, potentially resulting in significant cost reduction on operational expenditures. By considering both initial investments and long-term operational efficiency, warehouse operators can make informed decisions that align with their specific automation goals.

Determining Your Warehouse Needs: Factors to Consider in Selection

When selecting between Automated Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs) for your warehouse, it's essential to first assess your specific operational needs. Consider the layout of your warehouse. An AGV typically follows predetermined paths and is ideal for structured environments with defined routes, while AMRs can navigate dynamically and adapt to changes in layout, making them suitable for more complex environments. Understanding the layout will help you determine which technology better aligns with your workflow and space optimization goals.

Another crucial factor to consider is the scalability of your operations. If you anticipate growth or changes in your inventory management needs, selecting a system that can easily adapt is vital. AMRs offer more flexibility in scaling operations, thanks to their ability to learn and map the environment autonomously. Additionally, evaluate the types of goods you handle; for instance, if you work with multi-sized items that require varied handling, AMRs may provide better support due to their advanced navigation and lifting capabilities. Balancing these factors will guide you toward the most suitable solution for enhancing your warehouse efficiency.

Related Posts

-

How to Choose the Right AMR Robot for Your Business Needs

-

Understanding the Future of Logistics with AGV AMR Technology Innovations

-

Why is AGV Technology Revolutionizing Material Handling in Warehousing?

-

Enhancing Warehouse Efficiency: The Impact of AGV Systems on Operational Costs and Throughput

-

Top 5 Picking Robots Transforming Warehouse Efficiency in 2023: Industry Insights & Data

-

Top 10 AGV Vendors Revolutionizing Warehouse Automation and Logistics in 2023