How to Choose an Automated Material Handling System in 2026?

In 2026, selecting an automated material handling system demands careful consideration. The global market for these systems is projected to reach $38 billion by 2026, according to a recent report from Markets and Markets. This growth reflects a surge in e-commerce, where efficiency is king. Companies are increasingly relying on these systems to streamline operations.

Industry expert Dr. Emily Roberts points out, "Choosing the right automated material handling system is crucial for competitiveness." Her insights underscore the need for businesses to evaluate their unique needs. A one-size-fits-all approach may lead to costly mistakes.

Considerations often include system flexibility, integration capabilities, and space constraints. Complex supply chains exacerbate the challenge. Companies must not only think about current needs but anticipate future demands as trends evolve. Ultimately, the right system can transform logistics but requires thoughtful assessment.

Understanding Automated Material Handling Systems and Their Importance

Automated material handling systems (AMHS) are becoming essential in modern warehouses. They improve efficiency, reduce costs, and enhance safety. These systems manage the movement of goods, from storage to shipment. With the rise of e-commerce, the demand for efficient handling systems has never been greater.

Understanding AMHS involves recognizing its components. Conveyors, automated guided vehicles, and robotic pickers are vital. Each element plays a crucial role in streamlining operations. However, not all systems work well for every facility. Different warehouses have unique layouts and workflows. It's important to reflect on specific needs before deciding.

Despite the benefits, there are challenges. Initial costs can be high. Maintenance can be complicated. Training staff to use advanced technology also requires time and resources. Overlooking these factors might lead to wasted investments. The choice of an AMHS should be well thought out. It must align with current operations for lasting success.

Evaluating Key Factors in Material Handling System Selection

Choosing an automated material handling system involves multiple factors. A thorough evaluation of different elements is crucial. Begin by assessing the volume of material to be handled. Consider the variety of products. Systems should be flexible enough to accommodate changes in inventory.

Space constraints are essential. Warehouse layout impacts system effectiveness. A well-planned system should optimize space usage. Consider the type of operations performed. Systems may differ in efficiency based on specific tasks. It’s vital to match the system capabilities to your operational needs.

Cost is always a concern. Balance initial investment with long-term savings. Analyze potential maintenance needs. Sometimes, cheaper systems may lead to higher costs over time. Don’t overlook the importance of scalability. As your business grows, the system should adapt. Reflect on past choices and their consequences. Each decision shapes future operations.

How to Choose an Automated Material Handling System in 2026? - Evaluating Key Factors in Material Handling System Selection

| Factor | Description | Importance (1-5) | Current Trends |

|---|---|---|---|

| Cost Efficiency | Evaluating the total cost of ownership including installation, operation, and maintenance. | 5 | Increased focus on ROI and long-term savings. |

| Flexibility | Ability to adapt to changes in the operation such as volume fluctuations and product types. | 4 | Growing demand for adaptable systems as markets evolve. |

| Technology Integration | Compatibility with current systems and use of IoT and AI technology. | 5 | Increased reliance on smart technology for efficiency. |

| Space Utilization | Maximizing the effective use of space in warehouses or factories. | 4 | Trend towards vertical storage solutions and compact systems. |

| Scalability | Ease of expanding the system to meet future demands. | 4 | Demand for systems that can grow with the business. |

| Safety Features | Inbuilt safety measures to protect workers and equipment. | 5 | Heightened focus on workplace safety protocols. |

Analyzing Different Types of Automated Handling Technologies

When selecting an automated material handling system, understanding the various technologies is crucial. There are several options available, each with distinct features and benefits. For instance, Automated Guided Vehicles (AGVs) are highly flexible. They can transport goods without a fixed route. According to recent industry reports, AGV usage has grown by 30% in logistics sectors over the past year. However, some facilities still struggle to integrate this technology effectively.

Conveyors also remain popular. They are efficient for moving high volumes of goods. A study indicates that implementing a conveyor system can reduce handling costs by up to 20%. Yet, they require significant floor space and can be inflexible. Assessing the layout of your operation is important. These factors highlight the need for careful planning.

Tips: Consider the future scalability of each system. Will it adapt to evolving business needs? Also, reflect on training requirements for your workforce. Are they prepared to handle new technology? Understanding these aspects ensures a smoother transition and better long-term outcomes.

Automated Material Handling Technologies Usage in 2026

Identifying Industry-Specific Requirements and Challenges

Choosing the right automated material handling system in 2026 requires careful consideration of specific industry needs. According to a recent market report, over 70% of warehouses face unique challenges related to space constraints and inventory management. These challenges vary significantly across industries, such as e-commerce and manufacturing. E-commerce demands rapid, flexible operations, while manufacturing may focus on precision and safety.

Additionally, many businesses struggle with integrating new systems into existing workflows. A study indicated that 60% of companies encountered disruptions during implementation. Industry-specific requirements must be addressed early in the decision-making process. For example, food and beverage industries prioritize hygiene and compliance, while automotive sectors may need tailored solutions for heavy parts.

Many organizations also underestimate their growth potential. A report from last year highlighted that 58% of businesses fail to scale their operations effectively due to inadequate material handling systems. It's crucial to evaluate long-term needs alongside immediate requirements. This can help avoid pitfalls and enhance efficiency across operations. Regular assessments and flexible systems can ensure that evolving needs are met.

Future Trends in Automated Material Handling Systems for 2026

In 2026, automated material handling systems will likely evolve significantly. These systems will incorporate advanced technologies such as AI, robotics, and IoT. This will lead to increased efficiency and reduced labor costs. Businesses will focus on flexibility to adapt to changing demands.

Tips: Consider the space and layout of your facility. A well-optimized design can enhance the effectiveness of these systems. Pay attention to integration capabilities. A system that seamlessly connects with existing operations saves time and reduces errors.

The rise of sustainability will shape choices in material handling. Eco-friendly technologies could become a priority. However, some companies may struggle with the transition. They might find it challenging to retrain staff or modify workflows. It’s essential to plan ahead.

Tips: Assess your current processes. Identify areas for improvement before implementation. This will help you avoid disruptions. Maintenance plans should also be realistic. Neglecting this can lead to costly downtimes.

Related Posts

-

Understanding the Future of Logistics with AGV AMR Technology Innovations

-

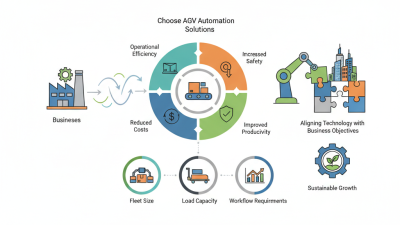

How to Choose the Right AGV Automation Solution for Your Business Needs

-

Top 10 AI and Robotics Innovations Transforming Industries Today

-

How to Ensure Robot Safety Standards are Met in 2025

-

Top 5 Picking Robots Transforming Warehouse Efficiency in 2023: Industry Insights & Data

-

Understanding the Importance of Robot Safety in Modern Automation