How to Choose the Right AGV Automation Solution for Your Business Needs

In today's rapidly evolving industrial landscape, businesses are increasingly turning to AGV automation solutions to enhance operational efficiency and reduce costs. According to a recent report by Transparency Market Research, the global automated guided vehicle market is projected to reach USD 10.5 billion by 2027, growing at a CAGR of 15.1%. This growth exemplifies the significant impact that AGV automation can have on streamlining logistics, improving safety, and increasing overall productivity.

John Smith, a leading expert in industrial automation, highlights the importance of selecting the appropriate AGV system for specific business needs: "Choosing the right AGV automation solution is not just about adopting technology; it's about aligning it with the operational goals and unique challenges of your organization." His insights underline the necessity of a strategic approach to AGV integration, emphasizing that companies must consider factors such as fleet size, load capacity, and workflow requirements to maximize the benefits.

As organizations seek to remain competitive in their respective markets, understanding how to choose the right AGV automation solution becomes paramount. By aligning AGV technology with business objectives, companies can not only enhance their operational capabilities but also position themselves for sustainable growth in an automated future.

Understanding Different Types of AGVs and Their Applications in Industry

Automated Guided Vehicles (AGVs) are revolutionizing logistics and material handling across various industries. Understanding the different types of AGVs is crucial for businesses seeking to optimize their operations. The most common types include tow vehicles, unit load carriers, and pallet trucks. Tow vehicles are designed to pull one or multiple trailers, making them suitable for transporting goods over long distances within a facility. Unit load carriers, on the other hand, are ideal for moving individual items or grouped products and are often utilized in warehouses where diverse types of loads are processed. Pallet trucks are specifically engineered for handling pallets and are widely used in storage areas for efficient stock management.

Each AGV type serves unique applications, tailored to meet specific industry needs. For instance, in manufacturing environments, tow vehicles can streamline assembly line operations by ensuring that parts are delivered just in time. Meanwhile, unit load carriers can enhance order fulfillment in e-commerce by efficiently transporting items from storage to packing stations. Additionally, pallet trucks are prevalent in retail and distribution centers, where they are indispensable for managing inventory. As businesses assess their automation needs, recognizing these distinctions among AGVs will empower them to select the solution that best aligns with their operational goals.

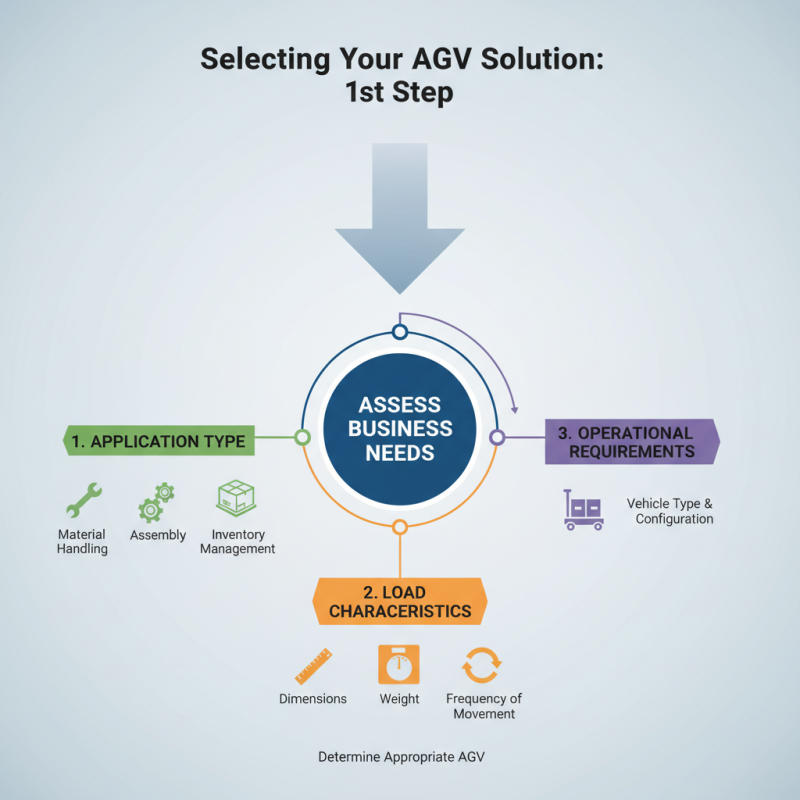

Assessing Your Business Needs: Key Factors in AGV Selection

When selecting an Automated Guided Vehicle (AGV) solution, the first step is to thoroughly assess your business needs by evaluating several key factors. Understanding the specific application for which the AGV will be used is crucial; whether it’s for material handling, assembly, or inventory management, different AGVs are designed for different tasks. Consider the types of loads that will be transported, their dimensions, weight, and the frequency of movement. This helps in determining the appropriate vehicle type and configuration that aligns with your operational requirements.

Another vital consideration is the layout of your facility. The design of the workspace, including constraints such as narrow aisles, ramps, and key access points, will dictate the suitability of various AGV models. Additionally, analyze the existing workflow and how AGVs can integrate seamlessly into current operations without causing disruptions. This includes assessing compatibility with other automated systems in place. By paying close attention to these factors, businesses can choose an AGV solution that not only meets their requirements but also enhances productivity and operational efficiency.

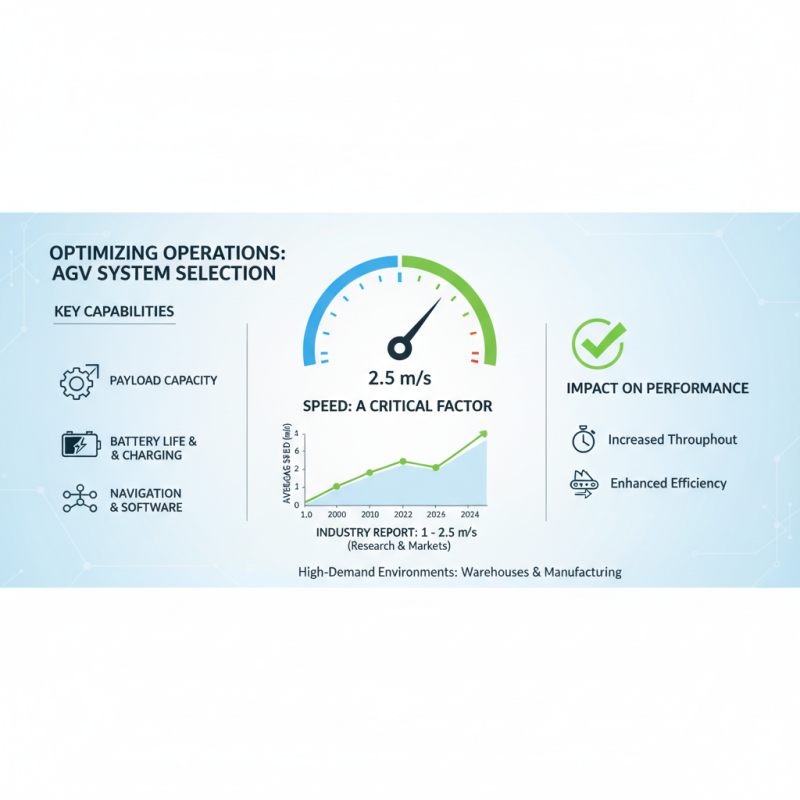

Evaluating AGV System Capabilities: Speed, Load Capacity, and Navigation

When selecting the right Automated Guided Vehicle (AGV) system, businesses must prioritize evaluating key capabilities that align with their operational requirements. Speed is one of these critical factors, as it directly affects throughput and efficiency. According to a recent industry report by Research and Markets, the average speed of AGVs has increased over the past few years, with many systems now operating between 1 to 2.5 meters per second. This speed enhancement can significantly improve operational performance, especially in high-demand environments like warehouses and manufacturing lines.

Load capacity is another crucial aspect to consider when choosing an AGV. Different applications necessitate varying weight capacities, and the right AGV must meet these specifications to ensure optimal performance. The same report indicates that the demand for AGVs with higher load capacities has risen, with many advanced models now supporting loads exceeding 1,500 kilograms. Businesses operating in sectors such as automotive and logistics often require AGVs that can handle heavier loads, making this feature paramount in their selection process.

Lastly, navigation capabilities are essential in ensuring that AGVs can operate effectively within complex environments. AGVs utilize a range of technologies for navigation, including laser guidance, magnetic strips, and visual systems. A comprehensive survey by the Association for Advancing Automation reveals that systems using sophisticated navigation technologies tend to improve route optimization, reduce downtime, and enhance the overall safety of operations. For businesses looking to implement AGVs, understanding these capabilities will be vital to selecting a solution that not only meets current demands but also supports future growth.

Cost Analysis: Budgeting for AGV Implementation and Maintenance

When planning for the implementation of Automated Guided Vehicles (AGVs) in your business, a comprehensive cost analysis is paramount. According to a report from the International Federation of Robotics, companies can expect the initial investment for AGV systems to range from

$250,000 to $1 million, depending on the complexity and scale of the operations. This includes the costs for the AGVs themselves, as well as necessary infrastructure modifications, integration with existing technology, and software solutions that facilitate operational efficiency.

In addition to the upfront costs, ongoing maintenance and operational expenses are crucial to consider. The same report highlights that maintenance costs can typically account for 10-15% of the total initial investment annually. Additionally, companies should anticipate training costs for their staff to effectively manage and operate AGV systems. These training costs can vary but are essential for maximizing the return on investment. In summary, a thorough budget that encompasses both initial and recurring expenses is essential for businesses to successfully implement AGV technology while ensuring long-term operational viability.

Future Trends in AGV Technology and Their Impact on Business Strategy

As businesses increasingly seek to enhance operational efficiency, the future trends in Automated Guided Vehicle (AGV) technology promise significant impacts on business strategy. One of the most notable trends is the integration of artificial intelligence and machine learning algorithms in AGVs. This evolution allows vehicles to adapt to dynamic environments, optimize their routes in real time, and learn from previous experiences. As AGVs become more intelligent, they can effectively reduce downtime and improve throughput, thereby becoming an indispensable part of a company’s logistics and supply chain strategy.

Furthermore, the move towards collaborative robots, or cobots, is another key trend influencing AGV technology. These advanced systems can work alongside human workers, enhancing safety and productivity in workplaces. The integration of AGVs with Internet of Things (IoT) solutions also enables better data collection and analytics, facilitating informed decision-making processes. By leveraging these technologies, businesses can not only streamline their operations but also create a more responsive and flexible supply chain that aligns with the evolving market demands and customer expectations.

In conclusion, as AGV technology continues to advance, businesses must strategically adapt to these trends to maintain competitive advantages. Embracing AI, collaborative robotics, and IoT integration will be critical for companies looking to harness the full potential of automation in their operations.

Future Trends in AGV Technology

This chart illustrates the projected growth in market demand for various types of Automated Guided Vehicles (AGVs) over the next five years. The data reflects the increasing adoption of AGVs across different sectors including manufacturing, logistics, and retail.

Related Posts

-

Understanding the Future of Logistics with Advanced AGV Systems in Modern Warehousing

-

Understanding the Future of Logistics with AGV AMR Technology Innovations

-

Enhancing Warehouse Efficiency: The Impact of AGV Systems on Operational Costs and Throughput

-

Top 10 AGV Vendors Revolutionizing Warehouse Automation and Logistics in 2023

-

Why is AGV Technology Revolutionizing Material Handling in Warehousing?

-

How to Choose the Right AMR Robot for Your Business Needs