How to Choose the Best Robot Tech for Your Business Needs

In today's rapidly evolving business landscape, the integration of robot tech has become a pivotal factor for competitive advantage. As companies increasingly turn to automation to enhance efficiency and productivity, the choice of the right robotic technology tailored to specific business needs is more critical than ever. Renowned robot tech expert, Dr. Lisa Tran, emphasizes this sentiment by stating, “Investing in the right robot tech can transform operations, but understanding the unique requirements of your business is essential to making the best choice.”

Selecting the optimal robot tech involves not only an assessment of available technologies but also a deep dive into the specific needs of your industry and operations. From manufacturing to logistics, the right robotic solutions can streamline processes, reduce costs, and improve service delivery. However, without a clear strategy and understanding of what each tech offers, businesses may find themselves facing challenges that outweigh the benefits. As we explore the considerations for choosing robot tech for your business, it is crucial to align technological capabilities with operational goals for maximum impact.

Identifying Your Business Objectives and Requirements for Robotics

Identifying your business objectives and requirements is crucial when choosing the best robot technology for your operations. Start by analyzing the specific challenges your business faces. Are you looking to automate repetitive tasks, improve precision in production, or enhance customer service? Clearly defining these needs will guide you towards the appropriate robotic solutions that align with your goals.

**Tip:** Create a list of your top three business objectives. This will help narrow down the types of robotics that could benefit your organization, whether it’s collaborative robots, industrial robots, or service robots.

Next, consider the scalability of the robotic solutions. As your business grows, your robotic technology should be able to adapt to increased demands and changing objectives. Look for systems that offer flexibility and integration capabilities with your existing processes.

**Tip:** Evaluate vendors’ offers for modular designs or software updates that allow easy scalability, ensuring that your robotic tech can evolve along with your business needs.

Evaluating Different Types of Robot Technologies Available

When evaluating different types of robot technologies available for your business, it's essential to consider the specific needs of your operations. Industry reports from the International Federation of Robotics (IFR) indicate a projected growth rate of 27% in industrial robot installations by 2025. This growth reflects the increasing reliance on automation across various sectors, from manufacturing to logistics. Assessing your business's current workflow can help identify which technologies offer the best return on investment. For example, collaborative robots, or cobots, are designed to work alongside human operators, making them ideal for tasks that require flexibility and human oversight.

**Tips:** Before making a decision, conduct a thorough analysis of your tasks. Understanding the specific functions you want robots to perform will steer you toward the relevant technology. Look into mobile robots if your operations require transport over large areas, and consider fixed robots for repetitive tasks on assembly lines. Additionally, prioritize solutions that offer easy integration with your existing systems, as seamless compatibility can alleviate potential disruptions.

Another trend supported by a recent McKinsey report highlights the adaptability of autonomous mobile robots (AMRs) in warehousing and inventory management. As businesses increasingly combine e-commerce and automation, AMRs can optimize logistics by enhancing order fulfillment efficiency. This adaptability is crucial in today's rapidly changing market, where consumer demands shift quickly. Establishing clarity on your operational needs will not only help in selecting the appropriate robot technology but also ensure you're future-proofing your business against evolving challenges.

How to Choose the Best Robot Tech for Your Business Needs - Evaluating Different Types of Robot Technologies Available

| Robot Type | Key Features | Best Suited For | Cost Range | Implementation Time |

|---|---|---|---|---|

| Industrial Robots | High precision, repetitive tasks, various payloads | Manufacturing, assembly lines | $25,000 - $150,000 | 3-6 months |

| Service Robots | User-friendly, autonomous navigation, customer engagement | Hospitality, retail | $10,000 - $50,000 | 2-4 months |

| Collaborative Robots (Cobots) | Easy to program, safe for human interaction, flexible | Small to medium enterprises, assembly assistance | $20,000 - $100,000 | 1-3 months |

| Agricultural Robots | Soil analysis, autonomous plowing, harvesting | Farming, vineyard management | $30,000 - $200,000 | 4-12 months |

| Logistics Robots | Automated inventory management, fast delivery | Warehousing, distribution | $15,000 - $80,000 | 2-6 months |

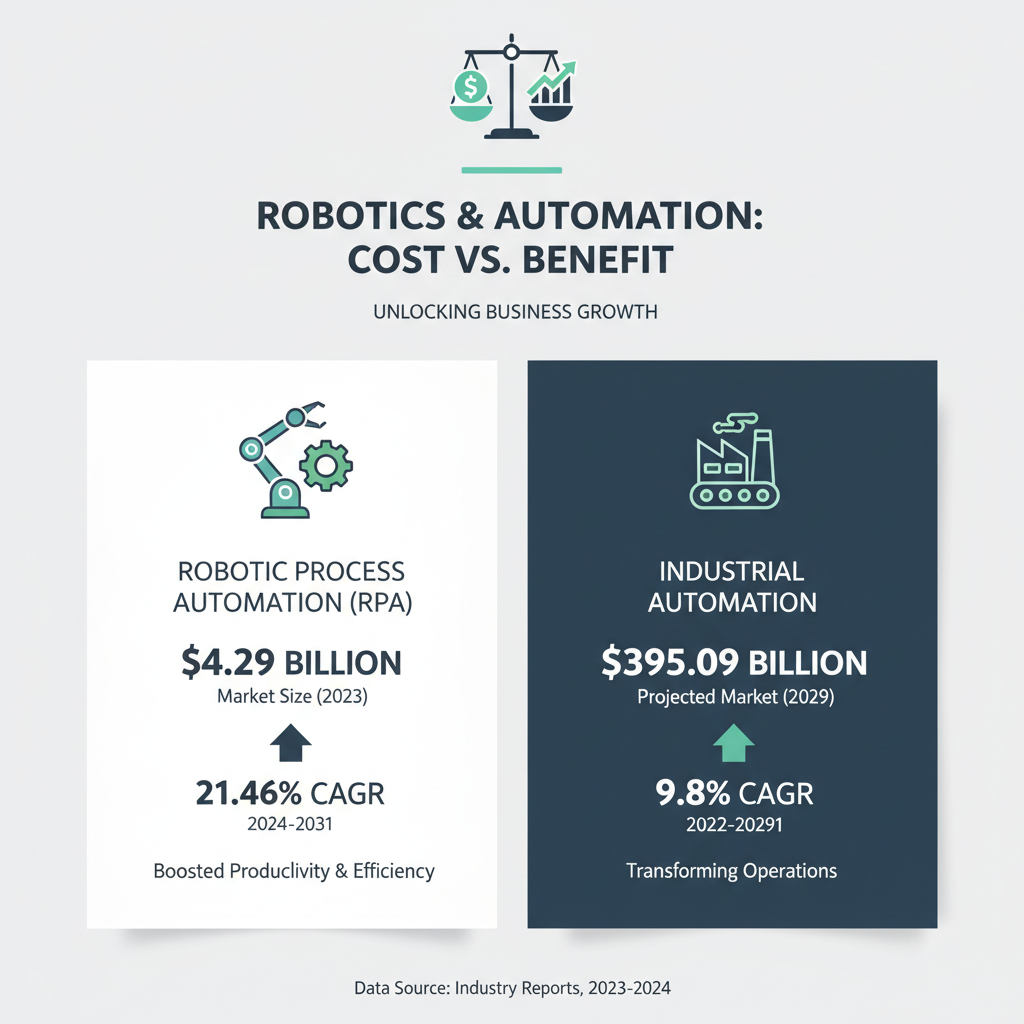

Analyzing Cost vs. Benefit for Implementing Robotics Solutions

When evaluating the implementation of robotics solutions for your business, analyzing the cost versus benefit is crucial. The robotic process automation market is estimated to reach $4.29 billion in 2023, with a robust compound annual growth rate (CAGR) of 21.46% anticipated from 2024 to 2031. This growth indicates a substantial return on investment for businesses adopting robotics technology to enhance productivity and efficiency. Similarly, the industrial automation market is projected to expand from $205.86 billion in 2022 to $395.09 billion by 2029, reflecting a CAGR of 9.8%. This significant upward trend underscores the potential impact automation can have on transforming operational processes across various industries.

Furthermore, exploring advanced robotics applications like AI in public management can lead to increased productivity and service quality. As organizations modernize through automation, the findings suggest considerable effects on workforce efficiency and enhanced service delivery. Understanding these market dynamics allows businesses to make informed decisions about the allocation of resources towards robotics solutions, ensuring that the benefits outweigh the costs while positioning themselves favorably within their respective sectors as they navigate the evolving technological landscape.

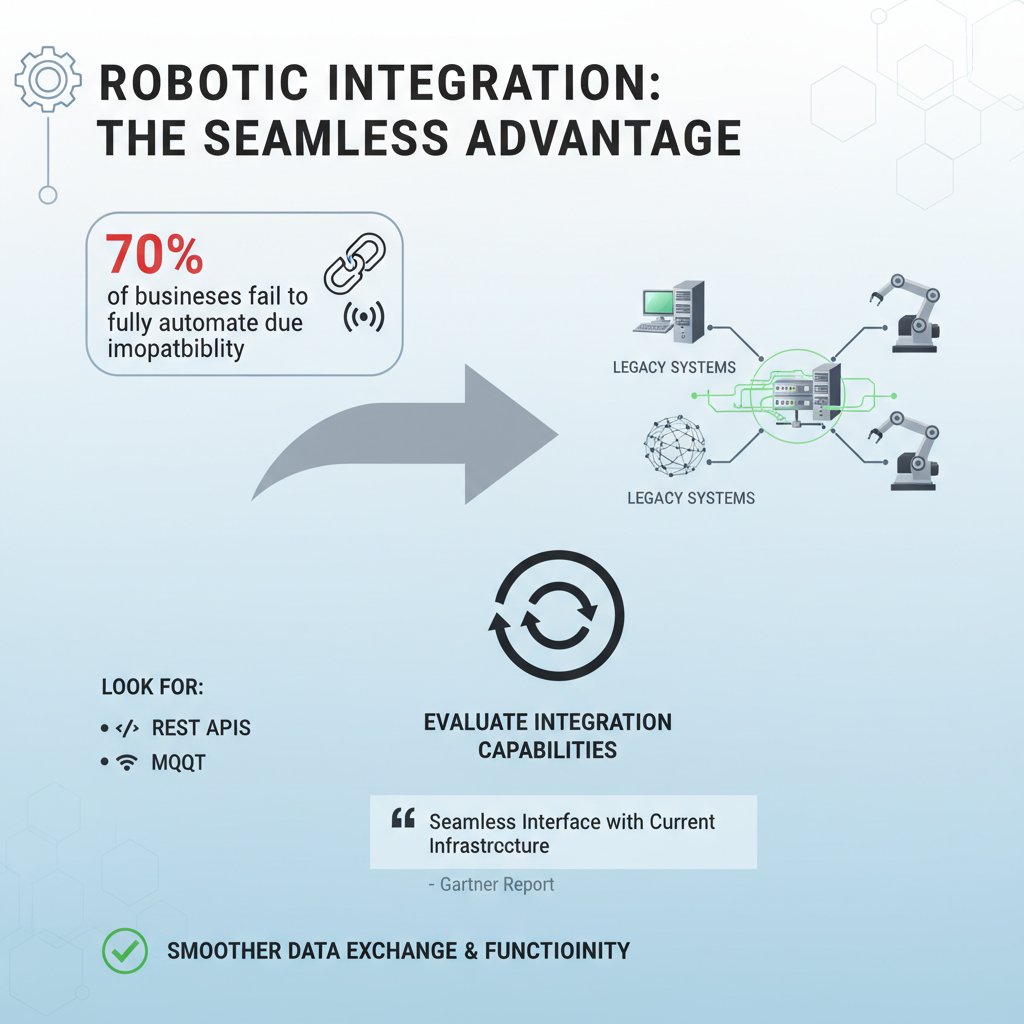

Assessing Integration Capabilities with Existing Systems

When selecting the best robotic technology for your business needs, evaluating integration capabilities with existing systems is pivotal. According to a recent report by Gartner, over 70% of businesses fail to fully automate processes due to incompatibility with legacy systems. This statistic underscores the importance of ensuring that any new robotic solutions can seamlessly interface with your current technology infrastructure. Businesses should look for robots that support standard communication protocols like REST APIs and MQTT, enabling smoother data exchange and functionality between systems.

Additionally, a study by McKinsey highlights that companies investing in robotic process automation (RPA) experience a 30-50% increase in operational efficiency, provided that these technologies are properly integrated into their workflow. A robust integration will not only enhance productivity but also minimize disruptions during the transition phase, allowing teams to adapt quickly.

Therefore, before making a decision, businesses must conduct thorough compatibility assessments and consider robotic systems that offer flexible integration options, ensuring that your investment will yield long-term benefits and adaptability to future technological advancements.

Selecting Vendors and Partners for Effective Robot Deployment

When selecting vendors and partners for effective robot deployment, it's essential to evaluate potential collaborators based on their experience in your specific industry. Look for companies that have a proven track record of successful robot integrations and can demonstrate tangible results. Consider their technological capabilities, support services, and whether they offer customization options to suit your unique business requirements. Engaging with partners who understand your operational challenges can facilitate smoother integration processes and enhance overall effectiveness.

Furthermore, effective communication and support are crucial in any vendor relationship. Ensure that the partners you choose are committed to providing ongoing training and technical assistance. This will not only help you maximize the utility of your robotic systems but also ensure that your team is equipped to handle unexpected challenges that may arise post-deployment. Establishing clear lines of communication will foster collaboration and allow for continuous improvement in your robotic operations, ultimately driving better outcomes for your business.

Robot Technology Investment by Industry in 2023

This chart illustrates the investment in robot technology across various industries in 2023. The data shows how different sectors prioritize automation to enhance efficiency and productivity.

Related Posts

-

Top 5 Robotics in Supply Chain: Revolutionizing Efficiency and Productivity

-

10 Automation Robotics Tips to Maximize Efficiency in Your Processes

-

Understanding the Future of Logistics with Advanced AGV Systems in Modern Warehousing

-

Understanding the Importance of Robot Safety in Modern Automation

-

Top 5 Picking Robots Transforming Warehouse Efficiency in 2023: Industry Insights & Data

-

How to Choose the Right AMR Robot for Your Business Needs