2026 Best Picking Robots for Efficient Automation Solutions?

As the demand for automation grows, picking robots have emerged as a pivotal solution in various industries. Industry expert Dr. Emily Chen states, "The future of logistics relies heavily on intelligent picking robots." These machines streamline the workflow, enhance productivity, and reduce labor costs. With advancements in technology, the capabilities of these robots have greatly improved.

In 2026, choosing the best picking robots means understanding their features and limitations. Many companies see the potential benefits, yet some still hesitate. The initial investment can be daunting, limiting access for smaller businesses. Each robot's efficiency must be carefully evaluated against operational needs.

Additionally, it’s crucial to reflect on integration challenges. Not all picking robots easily adapt to existing systems. The implementation requires careful planning and training for staff. As industries explore automation, the perfect picking robot remains a balance between innovation and practicality. In a rapidly evolving landscape, businesses must stay informed to make the best choices.

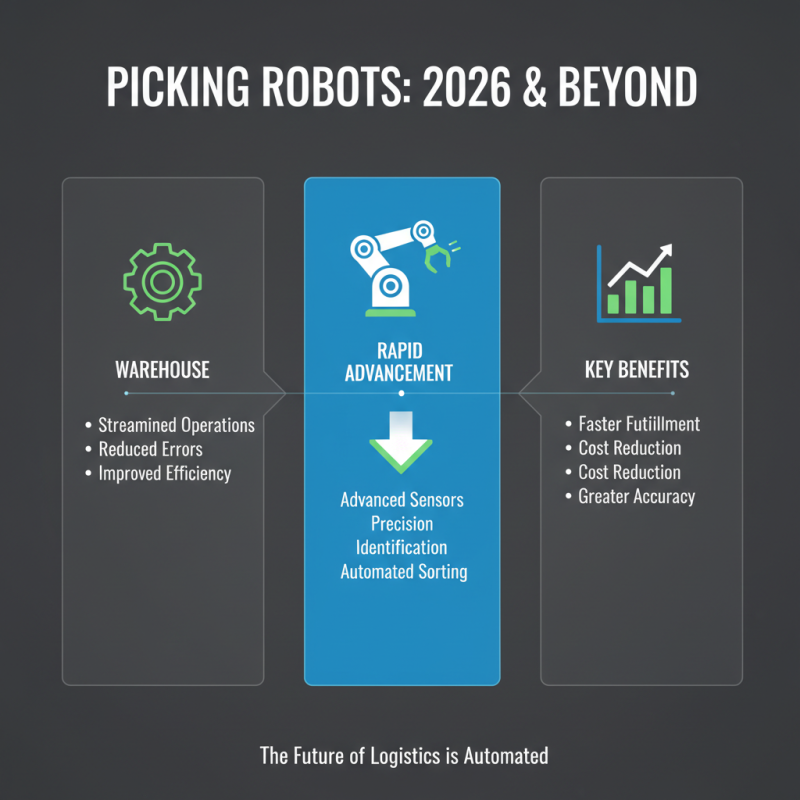

Overview of Picking Robots in 2026

In 2026, picking robots are advancing rapidly. These machines are essential for warehouses and distribution centers. They streamline operations, reduce errors, and improve efficiency. Many robots now feature advanced sensors. These help them identify and sort items with precision.

However, challenges remain. Some robots struggle to pick delicate items without causing damage. Performance can vary based on the environment. Bright lights or noisy conditions may disrupt their functionality. Maintenance is another concern. Regular servicing is needed to ensure these machines operate smoothly.

Innovation is vital, but we must address these concerns. Developing robots that adapt to various conditions is crucial. The future of automation depends on improving their reliability. With the right focus, these picking robots can significantly enhance productivity in 2026 and beyond.

Key Features of the Best Picking Robots

Picking robots are becoming essential for efficient automation in various industries. They streamline processes

while minimizing errors. When choosing a picking robot, several key features should be considered for optimal performance.

One crucial aspect is the robot's mobility. Many models navigate complex warehouse layouts with ease, enhancing productivity. Another vital feature is payload capacity. Some robots can carry heavy items, which is great for diverse operations. Sensors play a significant role too. They help with obstacle detection and precise picking. These functions reduce the risk of damage.

Tip: Evaluate the environment where the robot will operate. Every warehouse has unique challenges.

The software integration of these robots is also important. User-friendly software can simplify operations. However, ensuring compatibility with existing systems may require some adjustment.

It’s worth reflecting on how well new technologies align with existing processes.

Tip: Plan for training sessions. This fosters a smoother transition to automation.

Top Brands and Models for Efficient Automation

In 2026, picking robots are transforming automation in warehouses and distribution centers. These robots enhance efficiency in tasks like sorting and organizing goods. They minimize human error and optimize labor costs. However, the market is still evolving. Companies must assess which technologies best suit their needs.

Several models offer diverse capabilities. Some robots excel at speed, swiftly gathering items. Others are designed for precision, ensuring careful handling of fragile products. Evaluating these features is critical. However, some models fail in real-world conditions, highlighting the need for careful consideration before adoption.

User feedback often reveals mixed experiences. Some users appreciate the time saved, while others point out limitations in handling diverse product types. Training staff to work alongside robots is essential but can be challenging. Continuous learning is vital as technology evolves. The balance between automation and human oversight is an ongoing discussion in the industry.

2026 Best Picking Robots for Efficient Automation Solutions

| Model | Load Capacity (kg) | Speed (picks/min) | Dimensions (mm) | Battery Life (hrs) | Price Range ($) |

|---|---|---|---|---|---|

| Model A | 50 | 30 | 1000 x 600 x 400 | 8 | 20000 - 25000 |

| Model B | 30 | 45 | 1200 x 800 x 500 | 10 | 15000 - 20000 |

| Model C | 70 | 25 | 1100 x 650 x 450 | 12 | 25000 - 30000 |

| Model D | 40 | 50 | 1300 x 700 x 600 | 9 | 18000 - 22000 |

| Model E | 60 | 35 | 1250 x 650 x 500 | 11 | 22000 - 27000 |

Applications of Picking Robots in Various Industries

In recent years, picking robots have transformed various industries. Their applications range from warehousing to agriculture. A report by the International Federation of Robotics projected a 15% growth rate in the use of automation in logistics by 2025. This highlights the demand for efficient picking solutions.

In warehousing, robots now streamline operations. They sort and package items with remarkable speed. According to a 2022 study, companies that implemented picking robots saw a 30% increase in productivity. However, integrating these robots can lead to disruption. Employees may feel uncertain about their roles. Adequate training is essential to create a harmonious environment.

The agriculture sector is also benefiting. Robots now assist in harvesting crops like fruits and vegetables. A recent analysis showed that automated harvesters can reduce labor costs by up to 50%. Yet, the reliance on technology raises questions about food security. Dependence on robots could lead to gaps during maintenance or unexpected failures. Finding the right balance between automation and human labor remains a challenge.

Future Trends in Picking Robotics and Automation Solutions

The future of picking robotics is promising but not without challenges. Automation in warehouses is becoming more common. Yet, the integration of robots faces hurdles. Many systems struggle with complex environments. The unpredictability of items and layouts can complicate operations. This discrepancy often leads to inefficiencies. Design flaws within robotic systems can hinder adaptability.

As picking robots evolve, they will focus on flexibility. Future trends suggest that robots will work alongside humans seamlessly. This collaborative approach aims to enhance productivity. However, training these robots remains a critical issue. They must learn from varied scenarios and adjust quickly. Adaptation is not always guaranteed, making this a continuous area for improvement.

Sensor technologies will play a vital role in advancements. Robots must accurately identify and pick objects. Yet, misidentification can lead to costly errors. Consumers will demand more reliability as automation increases. Balancing efficiency and precision is crucial for success in this fast-paced market. Developing robots that meet these expectations requires ongoing research and reflection.

2026 Best Picking Robots for Efficient Automation Solutions

Related Posts

-

2025 How to Choose the Right Mobile Robot for Your Business Needs

-

2025 How to Choose the Best Picking Robots for Your Warehouse Efficiency

-

Top 10 AGV Vendors Revolutionizing Warehouse Automation and Logistics in 2023

-

Understanding the Future of Logistics with Advanced AGV Systems in Modern Warehousing

-

10 Best AMR Robots Transforming Warehousing and Logistics in 2023

-

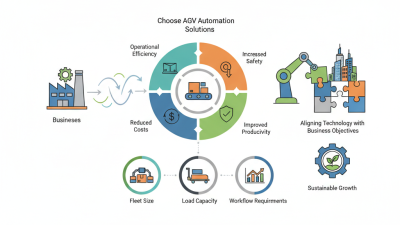

How to Choose the Right AGV Automation Solution for Your Business Needs