10 Best AMR Robots Transforming Warehousing and Logistics in 2023

In the ever-evolving landscape of warehousing and logistics, the integration of technology has become a cornerstone for efficiency and productivity. Among the most significant advancements are Autonomous Mobile Robots (AMR robots), which are transforming how goods are handled and transported within facilities. According to Dr. Sarah Thompson, a leading expert in robotics and automation, "AMR robots are not just tools; they are the future of operational agility in logistics." Her insights highlight the transformative power these robots hold in streamlining processes, enhancing accuracy, and reducing operational costs.

As businesses strive to keep pace with increasing demands and supply chain complexities, AMR robots have emerged as a viable solution to traditional challenges. These sophisticated machines can navigate dynamic environments, working collaboratively alongside human workers to optimize workflows. By implementing AMR technology, warehouses can expect improved efficiency and a significant boost in productivity, redefining the way goods move through supply chains. In this analysis, we will explore the ten best AMR robots leading the transformation of warehousing and logistics in 2023, showcasing their features, benefits, and the role they play in shaping the future of the industry.

Overview of Autonomous Mobile Robots (AMRs) in Warehousing

Autonomous Mobile Robots (AMRs) are revolutionizing the warehousing and logistics sectors by introducing advanced automation solutions that enhance efficiency and productivity. Unlike traditional automated systems which require fixed pathways, AMRs utilize sophisticated navigation technology that allows them to traverse dynamic environments. This adaptability enables these robots to seamlessly integrate into existing warehouse ecosystems, optimizing workflows and reducing the need for extensive infrastructural changes.

The deployment of AMRs in warehousing facilitates a range of operational improvements. They can efficiently handle material transport, inventory management, and even order fulfillment processes. This leads to decreased labor costs and increased throughput, as AMRs can operate continuously, working alongside human workers to support and enhance overall productivity. Furthermore, the data analytics capabilities embedded in many AMRs provide companies with insightful metrics about inventory movements and operational bottlenecks, allowing for informed decision-making and strategic optimization of warehouse operations.

Key Features of AMR Robots for Efficient Logistics Management

The adoption of Autonomous Mobile Robots (AMRs) in warehousing and logistics is rapidly reshaping the industry, particularly in enhancing efficiency and operational effectiveness. According to a recent report by market research firm ResearchAndMarkets, the global AMR market is projected to grow at a compound annual growth rate (CAGR) of approximately 22% between 2023 and 2030. AMRs are equipped with advanced features such as real-time navigation, obstacle detection, and autonomous routing, which enable them to transport goods seamlessly within warehouses. This technology minimizes human error and significantly reduces the time taken for internal logistics processes.

Key features of AMR robots include their ability to integrate with existing warehouse management systems and operate alongside human workers. This collaboration is crucial, especially as labor shortages continue to challenge the industry. The 2023 Logistics Management Survey indicates that over 65% of logistics professionals have reported increased reliance on automation to overcome workforce challenges. Furthermore, AMRs utilize AI-powered data analytics to optimize their operational routes based on real-time traffic and congestion data within warehouses. This capability can lead to a reduction in handling time by up to 30%, thereby accelerating overall productivity and reducing operational costs. As the technology continues to evolve, the deployment of AMRs is becoming indispensable for organizations aiming to streamline their logistics management strategies.

Top 10 AMR Robots Revolutionizing Warehouse Operations in 2023

Automated Mobile Robots (AMRs) are increasingly playing a pivotal role in revolutionizing warehouse operations in 2023. These intelligent systems not only streamline logistics but also significantly enhance efficiency in supply chain processes. According to a recent report by the Logistics Management Association, companies that implement AMR technology can expect a reduction of operational costs by up to 30%—a substantial saving in a world where margins are continually being squeezed.

AMRs are capable of performing tasks such as inventory management, order picking, and transportation of goods within warehouses. A study by the International Federation of Robotics indicated that the global market for logistics robots is projected to reach $20 billion by 2025, underscoring the rapid adoption of these technologies. AMRs improve accuracy and speed, with some robots achieving picking speeds that are 20% faster than human workers, allowing warehouses to keep up with the surging demand for quick delivery services.

**Tip:** When considering the integration of AMRs in your warehouse, ensure to assess the current layout and workflows to maximize their efficiency. Identifying bottleneck areas can allow for a more targeted deployment of robots, enhancing their productivity. Additionally, investing in training for your workforce on collaborating with AMRs can further streamline operations and reduce any potential friction between human and robotic workers.

Impact of AMR Technology on Supply Chain Efficiency and Cost Reduction

Autonomous Mobile Robots (AMRs) are revolutionizing the warehousing and logistics sectors by significantly enhancing supply chain efficiency and driving down costs. The integration of AMR technology enables firms to automate routine tasks such as picking, sorting, and transporting goods. This automation not only leads to faster operations but also minimizes human error, ensuring greater accuracy in inventory management. As businesses adopt AMR systems, they can optimize their workflows, reduce labor costs, and respond more swiftly to market demands.

Tips: When considering the implementation of AMR technology, assess your warehouse layout and operational needs. Start with a small pilot project to evaluate AMR performance and scalability before a full-scale rollout. Regular training for staff is also crucial to seamlessly integrate these robots into existing workflows, ensuring everyone understands how to work alongside these advanced systems.

Moreover, AMRs contribute to cost reduction by improving space utilization within the warehouse. With their ability to navigate and operate efficiently in tight spaces, AMRs can increase storage density and reduce the overall footprint needed for operations. This optimization results in lower overhead costs and can enhance the overall profitability of supply chain operations.

Tips: Conduct a thorough cost-benefit analysis to identify potential savings that AMRs can bring to your operations. Monitor key performance indicators after implementation to continually assess the impact of AMRs on your supply chain efficiency.

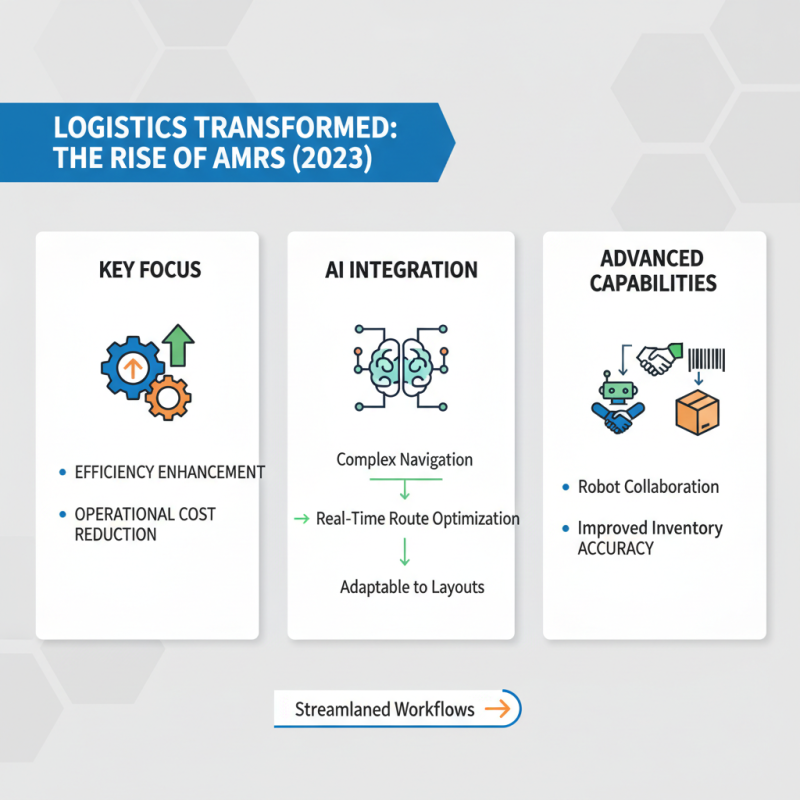

Future Trends in AMR Development and Their Role in Logistics

The logistics industry is undergoing a significant transformation with the rise of Autonomous Mobile Robots (AMRs). In 2023, the development of AMR technology is focused on enhancing efficiency and reducing operational costs. One major trend is the integration of artificial intelligence, enabling AMRs to navigate complex warehouse environments more effectively. These robots can optimize their routes in real-time, adapt to changing layouts, and even collaborate with other robots to streamline workflows. This evolution not only improves productivity but also enhances accuracy in inventory management.

Tips for adopting AMR technology include assessing your specific operational needs before implementation. Understand the areas where AMRs can provide the most value, such as repetitive tasks or high-volume picking. Additionally, ensure a seamless integration with existing systems to maximize benefits. Training staff to work alongside AMRs is also crucial, as it fosters a collaborative environment and enhances overall efficiency.

Another trend shaping the future of AMRs in logistics is the emphasis on sustainability. Many companies are exploring eco-friendly materials and energy-efficient designs in their AMR fleets. This shift not only addresses environmental concerns but also appeals to customers who value sustainability. As the market evolves, embracing these trends will be essential for businesses looking to stay competitive in the logistics space.

Related Posts

-

Enhancing Warehouse Efficiency: The Impact of AGV Systems on Operational Costs and Throughput

-

Top 10 AGV Vendors Revolutionizing Warehouse Automation and Logistics in 2023

-

Understanding the Future of Logistics with AGV AMR Technology Innovations

-

Top 10 Mobile Robots Revolutionizing Automation in 2023

-

Top 5 Robotics in Supply Chain: Revolutionizing Efficiency and Productivity

-

10 Automation Robotics Tips to Maximize Efficiency in Your Processes