Top 10 Benefits of Material Handling Robots for Your Business Efficiency

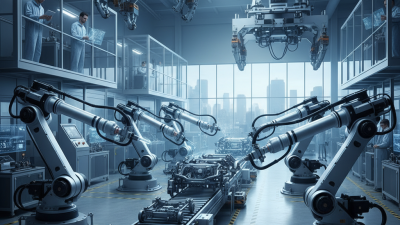

In today’s fast-paced industrial landscape, businesses are increasingly turning to automation to enhance operational efficiency. Among the most impactful advancements in this area are material handling robots, which streamline production processes and significantly improve productivity. According to a report by the International Federation of Robotics (IFR), the market for industrial robots is expected to grow by 12% annually, with material handling applications being one of the leading segments driving this growth. These robots not only reduce the likelihood of workplace injuries but also optimize the supply chain through improved speed and accuracy.

As noted by Dr. Mark O'Reilly, a leading expert in the field of automation and robotics, "The integration of material handling robots into manufacturing operations is not just a trend; it’s a paradigm shift that redefines how businesses operate." This sentiment underscores the importance of adopting robotic solutions for material handling to remain competitive in an ever-evolving market. By leveraging the capabilities of these robots, companies can enhance their efficiency, reduce operational costs, and maintain a high level of service quality. Embracing this technology represents a strategic move towards achieving long-term business success and sustainability.

Benefits of Enhanced Productivity Through Material Handling Robots

The implementation of material handling robots in various industries has been shown to significantly enhance productivity. According to a report by the Association for Advancing Automation (A3), factories that incorporate automation see a productivity increase of up to 30%. This surge in productivity can be attributed to several factors, including reduced cycle times and increased operational efficiency. By automating repetitive and physically demanding tasks, businesses enable their workforce to focus on more complex and value-added activities, thereby driving innovation and growth within the organization.

Furthermore, the use of material handling robots directly impacts the accuracy and reliability of operations. Studies indicate that the error rates in manual handling processes can be as high as 20%, while robots can achieve near-perfect accuracy. This not only minimizes waste but also enhances the overall quality of products, leading to greater customer satisfaction and loyalty. In addition, the adoption of robotics can help organizations respond more quickly to market demands, thereby improving their competitive edge. As per a recent survey by Deloitte, 59% of companies that implemented robotics reported noticeable improvements in their response times to customer orders. This strategic integration of material handling robots paves the way for streamlined processes and improved business efficiency, fostering a sustainable growth environment.

| Benefit | Description | Impact on Productivity |

|---|---|---|

| Increased Speed | Robots can operate faster than human workers in material handling tasks. | Boosts overall operational speed by up to 30%. |

| Reduced Labor Costs | Less reliance on manual labor can lead to significant cost savings. | Potentially lowers labor costs by 20-40%. |

| Consistency and Reliability | Robots provide consistent output and can work endlessly. | Enhances reliability, decreasing error rates by 15%. |

| Improved Safety | Minimizes human exposure to hazardous materials and environments. | Reduces workplace injuries by up to 50%. |

| Enhanced Space Utilization | Can work in tighter spaces and help optimize storage areas. | Increases warehouse space efficiency by 25%. |

| Scalability | Rapidly adapt to increased demand without significant downtime. | Facilitates growth in production capacity by 30%. |

| Data Collection | Robots can gather and analyze data for better decision-making. | Improves operational insights, enhancing efficiency by 20%. |

| Flexibility in Tasks | Can be reprogrammed to handle different tasks as needs change. | Adaptable, enabling a reduction in time spent on task switching. |

| Reduction in Waste | Precision handling reduces material waste during transport. | Can cut waste by up to 15%. |

| Return on Investment | Positive ROI due to reduced costs and enhanced productivity. | Typically sees ROI within 1-2 years. |

Reducing Labor Costs with Automation in Material Handling

The integration of material handling robots into business operations can significantly reduce labor costs, a crucial aspect in enhancing overall efficiency. According to a recent report from the Institute of Robotics and Automation, companies using automated material handling systems have seen a reduction in labor expenditures by up to 30%. This decrease not only stems from the automation of repetitive tasks but also allows human workers to focus on higher-value activities, thus optimizing productivity and workforce utilization.

Additionally, the Robotics Industries Association highlights that automating material handling processes can lead to a 50% reduction in operational downtime. Robots work around the clock without fatigue, handling tasks such as sorting, packing, and transporting goods efficiently. This uninterrupted operation minimizes delays and streamlines workflows, which in turn contributes to cost savings. Implementing robotics in material handling isn't merely about replacing human labor; it’s about creating a more agile and responsive business environment that can adapt to the fluctuating demands of the market while maintaining a tight control over [labor-related expenses].

Improving Workplace Safety and Reducing Injuries with Robotics

The integration of material handling robots in the workplace has shown significant potential in enhancing safety and reducing injuries among employees. According to the Occupational Safety and Health Administration (OSHA), manual material handling is among the leading causes of workplace injuries, accounting for approximately 30% of all reported incidents. By employing robots for tasks that involve lifting, transporting, and positioning heavy items, businesses can significantly decrease the physical strain on workers. A recent study by the Robotics Industries Association (RIA) indicated that organizations utilizing robotics for material handling experienced a 40% reduction in workplace injury rates.

The implementation of robotics not only protects employees from potential harm but also promotes a culture of safety. When workers are relieved of the burden of repetitive and strenuous manual tasks, they can focus on more skilled responsibilities, leading to improved job satisfaction and productivity. Additionally, the Autonomous Mobile Robots (AMRs) are designed to navigate complex work environments safely, which reduces not only injury risks but also minimizes the potential for costly operational disruptions. Research from industry analysts suggests that companies that invest in robotic automation for material handling can see a return on investment in as little as 12 months, with enhanced safety being a crucial component of that value.

Streamlining Inventory Management and Accuracy with Robotics

The integration of material handling robots has revolutionized inventory management and accuracy, boosting business efficiency significantly. These advanced robotics systems can streamline the entire inventory process by automating tasks such as picking, packing, and sorting. According to a report by the Robotics Industry Association, companies that have implemented robotic solutions in their facilities have reported up to a 30% reduction in operational costs, primarily due to decreased labor expenses and increased throughput. Moreover, robotic systems enhance accuracy, with error rates dropping by up to 50%, which leads to improved customer satisfaction and return on investment.

Tips for optimizing your inventory management with robotics:

- Ensure proper integration with existing Warehouse Management Systems (WMS) for seamless operations.

- Allow for real-time tracking and inventory updates, minimizing stock discrepancies.

- Regularly review robot performance metrics to identify areas for further improvement.

- Implement training programs for staff to collaborate effectively with robotic systems.

By embracing robotics for material handling, businesses can not only streamline processes but also allocate human resources to more strategic tasks, leading to a more agile and responsive operation. As the market continues to adapt, leveraging advanced technologies will be crucial to staying competitive in an increasingly automated world.

Increasing Flexibility and Scalability in Manufacturing Processes

The integration of material handling robots into manufacturing processes has significantly enhanced operational flexibility and scalability. As per a report from the International Federation of Robotics, the global stock of industrial robots reached approximately 3 million units in 2021, indicating a growing trend in automation. These robots are not only able to perform repetitive tasks with high precision and speed but can also be reconfigured easily for different manufacturing needs. This adaptability allows manufacturers to respond swiftly to changing market demands, optimizing their production lines for various product designs without significant downtime.

Moreover, a study by McKinsey & Company highlights that the use of automation and robotics in manufacturing can increase productivity by up to 30% while reducing labor costs by as much as 25%. This efficiency enables companies to scale their operations in response to fluctuating demand, providing a competitive edge in a rapidly evolving marketplace. Consequently, businesses can reduce lead times and improve overall service levels, ultimately enhancing customer satisfaction. The ability to quickly switch between different tasks and manage diverse workflows without extensive retraining or retooling leads to a more agile manufacturing environment, crucial for today’s fast-paced economy.

Related Posts

-

Enhancing Warehouse Efficiency: The Impact of AGV Systems on Operational Costs and Throughput

-

Top 10 AGV Vendors Revolutionizing Warehouse Automation and Logistics in 2023

-

10 Automation Robotics Tips to Maximize Efficiency in Your Processes

-

Top Trends in Automation Robotics Transforming Industries Today

-

10 Best AMR Robots Transforming Warehousing and Logistics in 2023

-

2025 How to Choose the Best Picking Robots for Your Warehouse Efficiency