Why Automated Guided Vehicles Are Revolutionizing Material Handling Industry?

The material handling industry is undergoing a significant change. Automated guided vehicles (AGVs) play a crucial role in this transformation. According to a recent market report, the global AGV market is expected to reach $7.8 billion by 2026, growing at a compound annual growth rate (CAGR) of 15.5% from 2021. These impressive figures highlight the increasing reliance on technology in logistics and warehousing.

AGVs enhance efficiency and reduce labor costs. They transport materials accurately and safely within facilities. A study shows that businesses using AGVs report up to a 30% reduction in operational costs. However, challenges still exist. Integration with existing systems can be complex. Staff training is essential to maximize the use of AGVs. Still, the benefits often outweigh these difficulties.

The adoption of automated guided vehicles is reshaping industry standards. Companies must adapt to stay competitive. As AGV technology evolves, so will the landscape of material handling. Future-proofing operations will demand strategic investments. In this changing environment, AGVs are not just a trend; they are a necessity.

Understanding Automated Guided Vehicles (AGVs) and Their Functionality

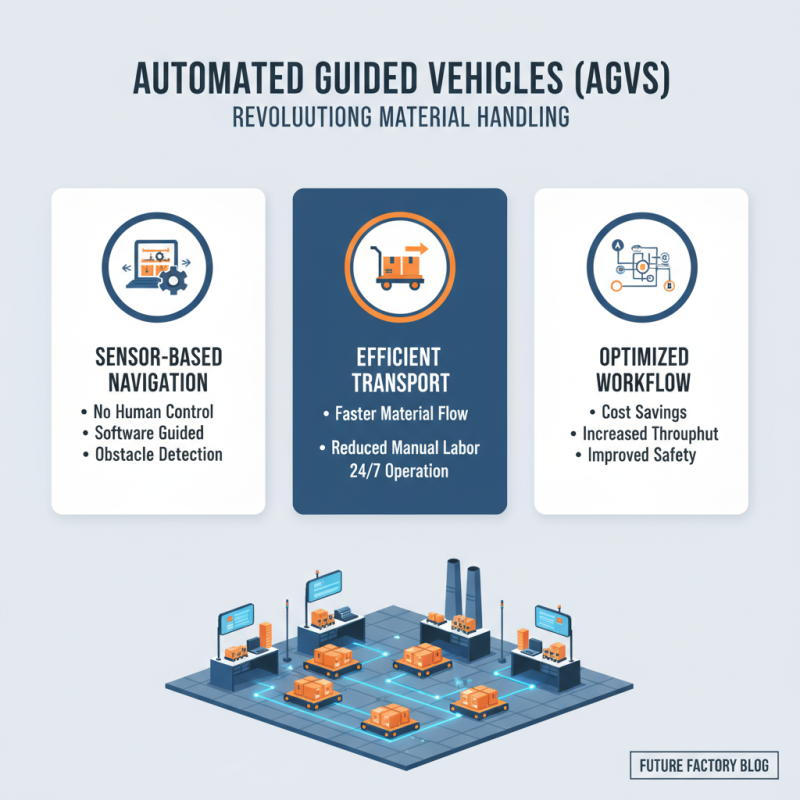

Automated Guided Vehicles (AGVs) are changing how we handle materials in warehouses and factories. These vehicles operate without direct human control, utilizing sensors and software to navigate. They can transport goods efficiently, reducing the time required for manual transportation. Imagine a factory floor buzzing with AGVs seamlessly moving materials from point A to point B, optimizing workflow.

The functionality of AGVs goes beyond simple transport. They can be programmed for various tasks, including pallet stacking and order picking. Some models even integrate with warehouse management systems, enhancing inventory tracking. However, not all implementations are perfect. There can be glitches in navigation, leading to stalls or wrong destinations. Feedback from operators can help improve the system. AGVs may lack the flexibility of human workers in complex environments, causing challenges in adaptation to dynamic situations.

Despite their advantages, reliance on AGVs requires careful planning. Each environment has unique characteristics that an AGV must adapt to. Organizations should assess space, pathways, and potential obstacles. Regular maintenance is crucial to ensure optimal operation. Balancing automation with human skills is still a topic worth pondering as AGVs become more prevalent in material handling.

Key Technologies Driving AGV Advancements in Material Handling

Automated Guided Vehicles (AGVs) are transforming the material handling industry. They constantly improve how goods move in warehouses and factories. Several key technologies are propelling these changes. For instance, Lidar and computer vision allow AGVs to navigate complex environments without human intervention. They ensure safety and efficiency, yet these systems occasionally misinterpret their surroundings.

Wireless communication technology plays a crucial role in AGV advancements. It allows real-time data exchange between vehicles and the central system. This integration leads to better decision-making. However, sometimes the network can fail, leading to delays. Achieving seamless connectivity is still a challenge.

Artificial intelligence is also enhancing AGV capabilities. AI algorithms enable better route optimization. AGVs can learn from past experiences, improving operational efficiency. But, there are moments where the system may struggle to adapt to unexpected obstacles. Continuous learning and adaptation remain vital for future success.

Impact of AGVs on Efficiency and Cost Reduction in Warehousing

Automated Guided Vehicles (AGVs) are significantly transforming the warehousing and material handling sector. These vehicles streamline operations and enhance efficiency in several ways. They can move goods quickly and accurately, reducing the time spent on manual tasks. This speed translates into faster order fulfillment and improved throughput.

Cost reduction is another vital impact of AGVs. By automating material handling, companies can lower labor costs. Employees can focus on more strategic tasks instead of repetitive movements. However, the initial investment in AGVs can be significant. Some businesses may wonder if the expected savings will justify the expenditure.

Beyond costs, AGVs bring a degree of flexibility. They adapt to different workflows and environments. Yet, the technology isn't flawless. System failures or connectivity issues can disrupt operations. Additionally, proper training is essential for staff managing AGVs. Without it, efficiency could drop, and safety might be compromised. Balancing these factors is critical for companies considering AGV integration.

Impact of AGVs on Efficiency and Cost Reduction in Warehousing

Challenges and Limitations of Implementing AGVs in Industry

Automated guided vehicles (AGVs) are transforming the material handling industry. However, implementing AGVs comes with challenges. One major issue is the initial cost. Companies often face high upfront investments. This can deter smaller businesses from adopting the technology. Additionally, the need for infrastructure changes can complicate matters. Integrating AGVs into existing systems may require significant modifications.

Another challenge is training staff. Workers need to adapt to new technologies. This learning curve can lead to downtime, affecting overall efficiency. Moreover, there's a reliance on technology that can be problematic. Technical failures can disrupt operations, causing delays in the supply chain. Companies must have contingency plans in place to mitigate these risks.

Compatibility with existing equipment can also be an issue. Not every vehicle can seamlessly work with AGVs. This can create logistical nightmares. Furthermore, safety concerns are paramount. AGVs operate alongside human workers, and accidents can happen. Companies must invest in proper safety measures to protect employees. Overall, while AGVs offer immense potential, their integration is not without hurdles. Companies must carefully evaluate their readiness to adopt this technology.

Why Automated Guided Vehicles Are Revolutionizing Material Handling Industry? - Challenges and Limitations of Implementing AGVs in Industry

| Dimension | Description | Impact Level | Implementation Difficulty |

|---|---|---|---|

| Cost | Initial investment in AGV systems and maintenance costs | High | Medium |

| Adaptability | Ability to integrate with existing systems and processes | Moderate | High |

| Safety | Ensuring safe operation alongside human workers | High | Medium |

| Technology | Reliability of navigation and control systems | High | High |

| Data Integration | Ability to analyze and leverage data generated by AGVs | Moderate | Medium |

Future Trends and Innovations in AGVs for Material Handling Solutions

Automated Guided Vehicles (AGVs) are changing the material handling landscape. These machines provide efficiency and flexibility in operations. They can navigate through busy warehouses and distribution centers with ease. However, the technology is not without challenges. The integration process can be complex. Companies may find it difficult to update existing systems to accommodate AGVs.

Future trends in AGVs point towards more sophisticated solutions. For instance, the rise of AI and machine learning enhances navigation capabilities. AGVs are expected to become even more autonomous in the coming years. Enhanced sensors will allow them to interact better with their environment. But are we ready for such advancements? As AGVs take over more tasks, workforce adjustment is crucial. Companies must consider retraining employees or risk losing talent.

Innovations like swarm technology could lead to improved efficiency. AGVs may work in groups, coordinating tasks seamlessly. This opens new possibilities for optimizing space and time in warehouses. Yet, reliance on technology raises concerns. What happens if systems fail? Backup plans and human oversight remain essential for a smooth operation. Adapting to changes in material handling requires careful thought and planning.

Related Posts

-

Understanding the Future of Logistics with AGV AMR Technology Innovations

-

Why is AGV Technology Revolutionizing Material Handling in Warehousing?

-

Top 10 Benefits of Material Handling Robots for Your Business Efficiency

-

2025 Guide: How to Choose Between AGV and AMR for Your Warehouse Needs

-

How to Choose an Automated Material Handling System in 2026?

-

How to Implement an Automated Guided Vehicle System in Your Warehouse Operations