How to Implement an Automated Guided Vehicle System in Your Warehouse Operations

Implementing an Automated Guided Vehicle System (AGVS) in warehouse operations can transform the efficiency and productivity of logistics management. According to Dr. Eva Zhang, a leading expert in robotics and automation, "The introduction of an automated guided vehicle system not only streamlines material handling processes but also significantly reduces operational costs." This statement highlights the potential impact that AGVS can have on modern warehouses struggling with labor shortages and high operational expenses.

As industries continue to evolve towards automation, the integration of AGVS can be a game-changer in optimizing warehouse workflows. These systems utilize advanced technology to navigate predefined paths, allowing for the seamless transport of goods throughout the facility. By incorporating AGVS, warehouses are equipped to improve accuracy in inventory management, enhance safety measures by reducing human error, and ultimately increase throughput.

This article will delve into essential strategies for effectively implementing an automated guided vehicle system within your warehouse operations, exploring the technological requirements, planning phases, and potential challenges. Whether you’re looking to upgrade your existing logistics setup or starting from scratch, understanding the practicalities of AGVS will ensure a smoother transition and a more efficient future for your operations.

Understanding Automated Guided Vehicle Systems in Warehouse Operations

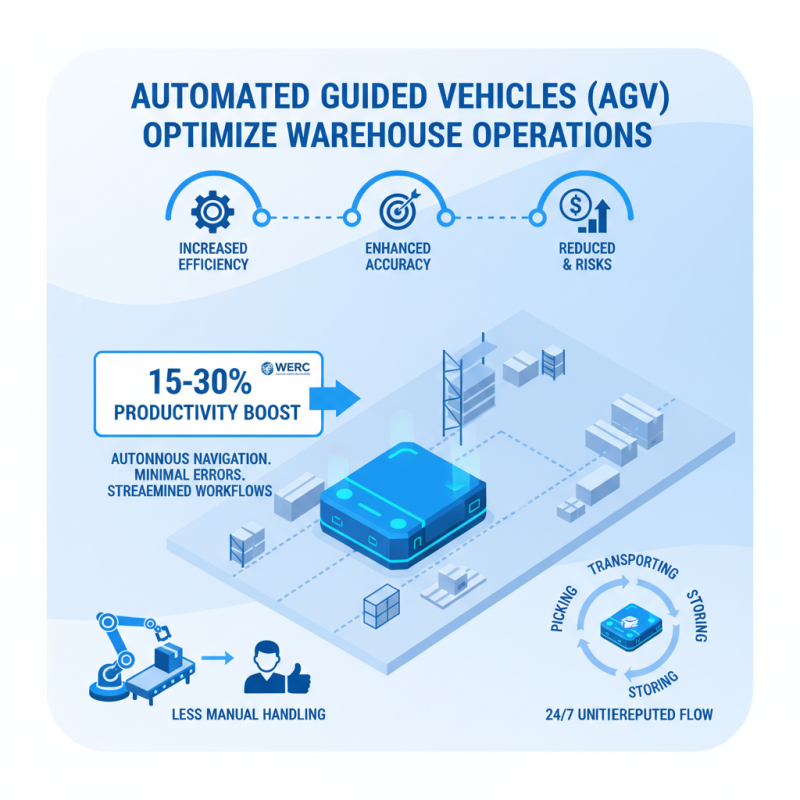

Automated Guided Vehicle (AGV) systems are transforming warehouse operations by enhancing efficiency and accuracy while reducing labor costs and operational risks. According to the Warehousing Education and Research Council (WERC), warehouses equipped with automated solutions see an average productivity increase of 15% to 30%. AGVs can navigate through predefined paths autonomously, effectively moving goods from one location to another without the need for human intervention, which minimizes errors related to manual handling and allows for streamlined workflows.

The integration of AGV technology not only optimizes space usage but also improves inventory management. A report from the MHI (Materials Handling Industry) indicates that 80% of warehouses planning to invest in automation cite AGVs among their top priorities. This shift towards automation is driven by the increasing demand for faster order fulfillment and the need to respond to labor shortages exacerbated by global economic changes. By employing AGVs, warehouses can maximize their operational capabilities, meeting customer expectations for speed and accuracy while positioning themselves competitively in the fast-evolving logistics landscape.

Key Benefits of Implementing AGV Systems in Inventory Management

Implementing Automated Guided Vehicle (AGV) systems in warehouse operations can significantly enhance inventory management by optimizing efficiency and accuracy. According to a report by McKinsey, warehouses that leverage AGV technology can increase their operational efficiency by up to 30%. These vehicles streamline material handling processes by autonomously transporting goods, which reduces labor costs and minimizes human errors that can lead to inventory discrepancies. With AGVs capable of working alongside other automated systems, they create a synergistic environment that boosts overall productivity.

One of the key benefits of AGV systems is their contribution to improved inventory accuracy. A study from the Journal of Supply Chain Management highlights that organizations implementing AGV solutions have reported inventory accuracy rates soaring to 99.9%. This high level of precision is crucial for maintaining optimal stock levels, reducing excess inventory, and minimizing stockouts.

Additionally, AGVs can operate continuously, allowing for real-time inventory tracking and replenishment enabling warehouses to respond more effectively to fluctuating demand patterns. The combination of labor savings and accuracy improvements positions AGV systems as a transformative tool in modern inventory management.

Steps to Evaluate Your Warehouse for AGV Integration

Evaluating a warehouse for Automated Guided Vehicle (AGV) integration involves several critical steps that can significantly enhance operational efficiency. First, a thorough assessment of the current layout is essential. According to a report by the Warehousing Education and Research Council, optimizing space utilization can lead to up to a 30% reduction in operational costs. An effective AGV system can streamline workflows by minimizing the distance items must travel within the warehouse. This means analyzing pick paths, storage locations, and identifying areas that can be enhanced through automation.

Next, it’s vital to examine the existing technology infrastructure. The International Federation of Robotics highlights that integrating AGVs can improve overall productivity by as much as 20%. This improvement is contingent on the compatibility of existing warehouse management systems with AGV control systems. A seamless integration process requires assessing software capabilities and ensuring that data flows between systems can be managed efficiently. Additionally, evaluating staff readiness and planning for training programs will ensure a smoother transition. A workforce that understands how to work alongside AGVs can help to mitigate resistance to change, further maximizing the return on investment in automation technology.

Selecting the Right AGV Technology for Your Specific Needs

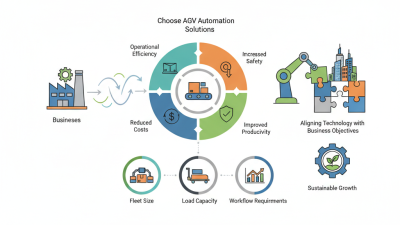

When selecting the right Automated Guided Vehicle (AGV) technology for your warehouse operations, it’s crucial to consider your specific needs and requirements. Different types of AGVs exist, including tow vehicles, unit load carriers, and hybrid AGVs, each suited for various tasks. Analyze your workflow and identify areas where AGVs can enhance efficiency, such as material handling, loading, or inventory management. Understanding your operational requirements is essential in making an informed choice.

Tips for selection:

1. **Assess Capacity and Load:** Determine the weight and dimensions of the materials you frequently handle to select an AGV that can accommodate your load without compromising performance.

2. **Evaluate Navigation Options:** AGVs can utilize various navigation technologies, such as laser, magnetic tape, or vision systems. Choose a system that aligns with your warehouse layout and operational needs.

3. **Consider Scalability:** As your warehouse operations grow, so should your AGV capabilities. Select a system that allows for easy integration of additional vehicles or functionalities to adapt to future demands.

Careful evaluation of these factors will help you choose the AGV technology that best aligns with your operational goals, maximizing efficiency and return on investment.

Automated Guided Vehicle System Technology Comparison

This bar chart compares different types of Automated Guided Vehicle (AGV) technologies based on their estimated costs in thousands of dollars. The data illustrates how varying technologies may fit different budgetary requirements in warehouse operations.

Best Practices for Training Staff on Automated Guided Systems

Training staff on automated guided vehicle (AGV) systems is essential for ensuring a smooth integration into warehouse operations. First and foremost, comprehensive training programs should be developed to introduce employees to the functionalities and benefits of AGV systems. This includes hands-on training sessions where staff can interact directly with the vehicles. Simulations or controlled environments can also be beneficial, allowing employees to practice troubleshooting and operating the AGVs without the pressure of live conditions.

Additionally, ongoing education is crucial as technology evolves. Regular workshops should be organized to keep staff updated on new features and best practices. Encouraging a culture of feedback can further enhance the learning process; employees should feel comfortable sharing their experiences and challenges with AGV systems. This collective knowledge can lead to improved operational efficiency and safety. Incorporating safety protocols and emergency response scenarios into training programs will empower employees to respond effectively to any potential issues while operating the AGV system.

How to Implement an Automated Guided Vehicle System in Your Warehouse Operations - Best Practices for Training Staff on Automated Guided Systems

| Training Topic | Description | Duration (Hours) | Training Method |

|---|---|---|---|

| Introduction to AGVs | Overview of Automated Guided Vehicles and their functions. | 2 | Lecture |

| Safety Protocols | Understanding safety measures while operating AGVs. | 1.5 | Workshop |

| Operating AGVs | Hands-on training for operating AGVs effectively. | 3 | Practical Training |

| Troubleshooting | Techniques for identifying and solving common issues. | 2 | Interactive Session |

| Maintenance Procedures | Guidelines for regular maintenance of AGVs. | 2.5 | Lecture & Demonstration |

Related Posts

-

How to Choose the Right AGV Automation Solution for Your Business Needs

-

Enhancing Warehouse Efficiency: The Impact of AGV Systems on Operational Costs and Throughput

-

How to Choose the Right AMR Robot for Your Business Needs

-

Why is AGV Technology Revolutionizing Material Handling in Warehousing?

-

2025 Guide: How to Choose Between AGV and AMR for Your Warehouse Needs

-

Understanding the Future of Logistics with Advanced AGV Systems in Modern Warehousing