Why is AGV Technology Revolutionizing Material Handling in Warehousing?

In recent years, AGV technology has emerged as a game-changer in the realm of material handling within warehouses. Automation is no longer a futuristic concept; it is a present-day solution that enhances efficiency, reduces labor costs, and improves safety in warehousing operations. As industry expert Dr. Emily Zhang, a leading authority on automation technologies, aptly stated, "AGV technology not only streamlines inventory management but also transforms the entire workflow, paving the way for smarter warehouses."

The rise of AGV technology represents a paradigm shift in how goods are transported and handled within storage facilities. No longer confined to traditional manual processes, warehouses are increasingly turning to automated guided vehicles to facilitate a seamless flow of materials. This innovation enables businesses to adapt swiftly to changing demands, optimize space utilization, and minimize errors associated with manual handling.

As organizations continue to face the pressures of rising consumer expectations and the need for operational efficiency, AGV technology stands at the forefront of this evolution. With its ability to operate autonomously and communicate with various warehouse systems, AGV technology not only enhances productivity but also sets the stage for future advancements in supply chain management. The question is not whether to adopt AGV technology, but rather how quickly can industries embrace this revolutionary shift to remain competitive in a fast-paced environment.

AGV Technology Overview: Definition and Core Components

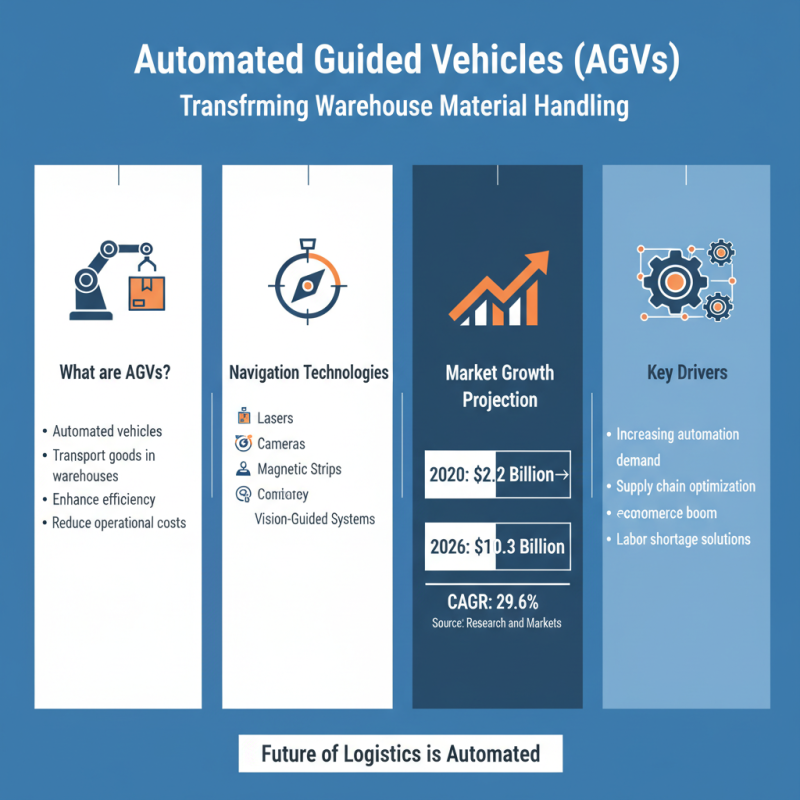

Automated Guided Vehicles (AGVs) are transforming the landscape of material handling in warehouses by enhancing efficiency and reducing operational costs. At their core, AGVs are automated vehicles designed to transport goods within a warehouse setting. They operate using various technologies, including lasers, cameras, and magnetic strips, to navigate through facilities safely and efficiently. According to a report by Research and Markets, the global AGV market is projected to grow from $2.2 billion in 2020 to $10.3 billion by 2026, indicating a compound annual growth rate (CAGR) of 29.6%. This remarkable growth is fueled by the increasing demand for automation in supply chain operations.

The essential components of AGV systems include navigation sensors, control systems, and power sources. Navigation sensors like LiDAR and infrared allow AGVs to map their environment and avoid obstacles, ensuring safe and precise movement. Additionally, sophisticated control software integrates AGV operations with warehouse management systems, optimizing routing and task assignments. Importantly, advancements in battery technology, particularly lithium-ion batteries, have led to longer operational times and quicker charging cycles, further enhancing the feasibility of AGVs in high-demand settings. As organizations strive for greater efficiency and accuracy, the robustness and reliability of AGV technology become indispensable for modern warehousing operations.

Market Growth: Statistics on AGV Adoption in Warehousing

The adoption of Automated Guided Vehicles (AGVs) in warehousing has seen remarkable growth in recent years, driven by the increasing demand for efficiency and accuracy in material handling. Recent statistics highlight that the AGV market is projected to expand significantly, with estimates suggesting a growth rate of over 15% annually in the next few years. This surge is attributed to the rising need for automation in warehouse processes, which allows businesses to streamline operations, reduce labor costs, and minimize human error.

Moreover, companies are increasingly incorporate AGVs into their supply chain management as they seek to optimize inventory management and improve the speed of order fulfillment. The integration of AGV systems can facilitate higher throughput rates and enhance overall productivity. As organizations strive to meet the ever-growing consumer expectations for faster delivery times, the adoption of AGV technology becomes imperative, emphasizing its pivotal role in modern warehouse operations. The data indicates that firms with AGV systems not only gain a competitive edge but also see a notable return on investment through improved efficiency and reduced operational costs.

Operational Efficiency: How AGVs Improve Accuracy and Speed

Automated Guided Vehicles (AGVs) are transforming the warehousing landscape by significantly enhancing operational efficiency through improved accuracy and speed. According to a recent report by the Warehousing Automation Market, integrating AGV technology can increase productivity by up to 25%, allowing warehouses to process goods more rapidly and reliably. AGVs operate by utilizing advanced sensors and navigation systems, permitting them to transport items across the facility with minimal human intervention. This automation reduces the likelihood of human error, which industry studies have shown accounts for up to 70% of inventory inaccuracies.

Furthermore, the speed at which AGVs can operate is another game changer for warehouses. Traditional manual handling can be time-consuming, often leading to bottlenecks in material flow. In contrast, AGVs can travel at speeds of up to 1.5 meters per second and can run continuously, optimizing the throughput of goods. The same Warehousing Automation Market report highlighted that companies implementing AGVs experienced a 30% reduction in lead times due to their ability to work around the clock without breaks. These improvements not only increase the speed of operations but also enhance service levels, as warehouses can fulfill orders more quickly and accurately, which is critical in today's fast-paced supply chain environment.

Cost Benefits: Analyzing the Return on Investment for Warehouses

Automated Guided Vehicle (AGV) technology is significantly transforming material handling processes in warehouses, particularly through its substantial cost benefits. According to a recent industry report by the Warehouse Automation Association, companies that implemented AGVs have seen operational costs decrease by up to 30% within the first year. The initial investment in AGV systems pays off rapidly, as they reduce the need for manual labor and minimize human errors, which can lead to costly mistakes and inefficiencies. Moreover, AGVs can operate continuously, maximizing productivity without the limitations of human workers, which further enhances their appeal.

Another critical aspect of the return on investment is the reduction in accidents and associated costs. The Occupational Safety and Health Administration (OSHA) highlights that workplace injuries can cost businesses $1 billion per week in lost productivity, compensation, and legal fees. By automating the movement of goods, AGVs contribute to a safer work environment, reducing the risk of accidents in high-traffic areas. This not only decreases insurance premiums over time but also fosters a more efficient and engaged workforce, which is an invaluable asset in the competitive landscape of warehousing. With effective training and integration, AGVs provide a robust solution that not only complements but enhances traditional warehousing operations, promising long-term savings and efficiency gains.

Future Trends: Innovations and Developments in AGV Technology

As the warehousing and logistics sectors continue to evolve, Automated Guided Vehicles (AGVs) stand at the forefront of innovative breakthroughs in material handling. Recent industry reports indicate that the AGV market is projected to grow at a CAGR of over 15% from 2023 to 2030, driven by advancements in automation technology and artificial intelligence. This growth is characterized by enhanced navigational capabilities, allowing AGVs to operate efficiently in increasingly complex environments. Innovations such as LiDAR and vision-based sensors have significantly improved AGV precision, reducing the likelihood of collisions and facilitating smoother operations.

Future trends suggest that AGV technology will continue to integrate with the Internet of Things (IoT) and machine learning, enabling real-time data analytics for better decision-making in warehousing operations. For instance, predictive maintenance powered by AI can minimize downtime, resulting in cost savings and improved productivity. Studies show that warehouses utilizing AGVs can reduce labor costs by as much as 30%, while simultaneously increasing order accuracy and throughput.

Tip: To maximize the efficiency of AGV systems in your warehouse, consider investing in ongoing training for your workforce. Familiarity with the technology can enhance operational effectiveness, driving both employee engagement and productivity. Emphasizing cross-training can also prepare staff for various roles as technology evolves. Another strategy involves regularly upgrading your AGV systems to ensure compatibility with the latest advancements and features that can further streamline operations.

Related Posts

-

Understanding the Future of Logistics with AGV AMR Technology Innovations

-

Enhancing Warehouse Efficiency: The Impact of AGV Systems on Operational Costs and Throughput

-

Understanding the Future of Logistics with Advanced AGV Systems in Modern Warehousing

-

Top 5 Robotics in Supply Chain: Revolutionizing Efficiency and Productivity

-

Top 10 AGV Vendors Revolutionizing Warehouse Automation and Logistics in 2023

-

How to Choose the Right AMR Robot for Your Business Needs